5-5

Tilt Control

Move the tilt mechanism both directions, tilting the mast

to both extents, watching for racking. Racking occurs

when the tilt cylinder strokes are uneven (One cylinder

bottoms before the other). The mast rails then twist,

eventually causing them to crack and separate. Proper tilt

degree is 3° forward and 3° backward maximum.

1.

To check for racking find a reasonably level floor area

to park the truck on and center the mast on the truck.

2.

Raise the mast about 36” (914 mm) from the floor

and tilt the mast full forward and backward several

times watching for twisting at the ends of the stroke.

3.

If there is any twisting or racking, both tilt cylinder

rods must be readjusted. Remove the truck from

service immediately and repair.

CAUTION

Side-Shift Control

Hold down the side shift control, moving the mast left and

right several times back and forth to both extents. Listen

for any abnormal noise that maybe caused by binding in

the side-shift mechanism. If any binding is detected apply

grease to the bearing pads immediately.

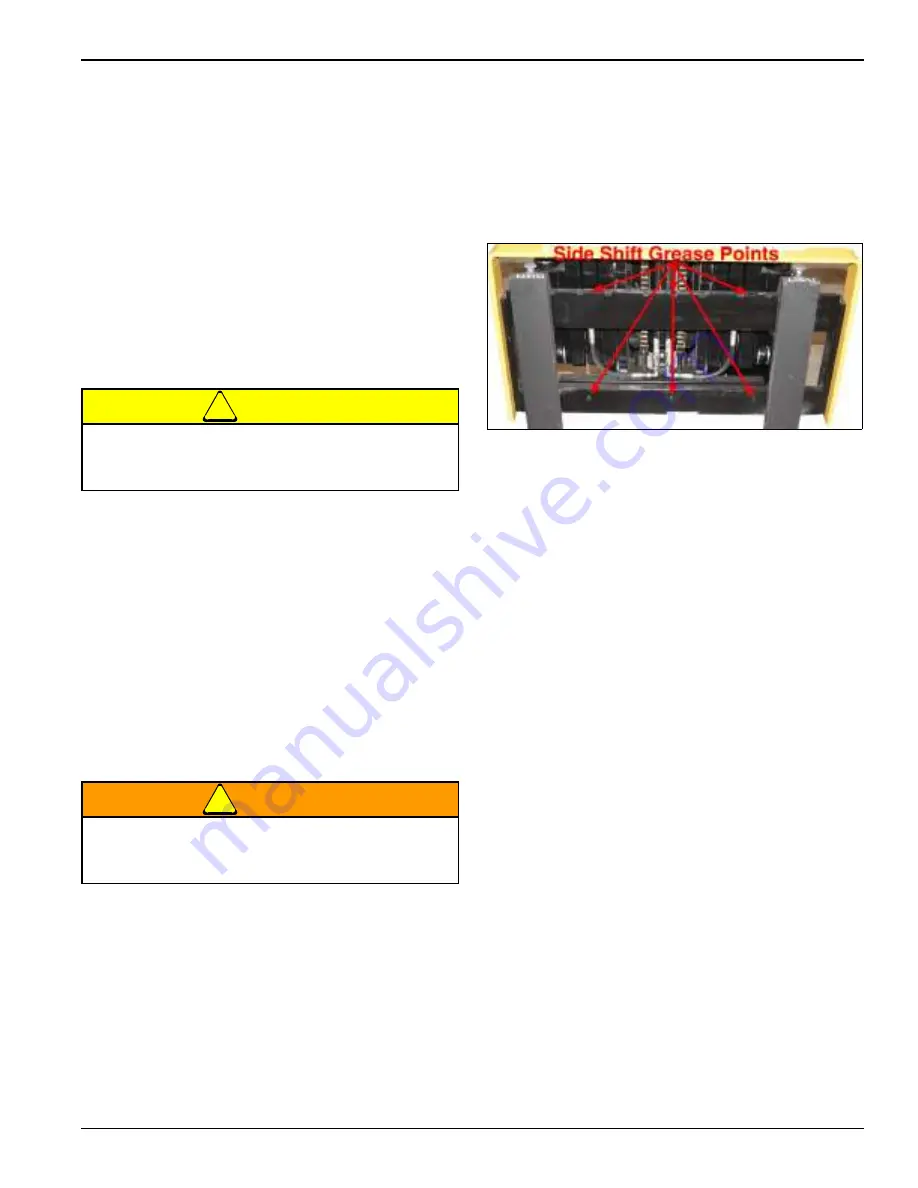

The side shift bearing pads are located within the slide

channels above and below the side shift assembly. The

channels are lined (sides, top and bottom) with strips of

low-friction plastic pads, embedded with molybdenum

di-sulfide, an inorganic lubricant. During the first week of

operation it is recommended to lubricate these pads once

every day to allow the grease to permeate the pads

completely. See Figure 5-5.

WARNING

1.

Shift the mast to its full left position, as viewed from

the operator’s compartment and set the Keyswitch to

off and remove the key.

2.

Before lubricating the bearing pads and channels

wipe off any excess lubricant and dirt buildup from

within the channels.

3.

Using a small brush paint a thin film of grease to the

sides, top and bottom of the side-shift channel

surfaces reachable with the mast in this position.

4.

Apply a little extra grease to the top surface of the

bottom channel pads.

5.

Turn the truck back on and shift the mast to its full

right position and then turn Keyswitch back to the off

position and remove key.

6.

Repeat grease procedure that was done on the left

side.

Figure 5-3: Side Shift Grease Points

Directional Control

Rock the directional switch forward to put the truck in

forward operation. Verify control input by observing

direction arrow on dash display. Repeat for the reverse

direction by rocking the direction switch backwards.

Static Return to Off (SRO) Function

The static return to off (SRO) is a built in safety feature to

prevent accidental truck movement.

To check the SRO:

1.

Get in the operator’s seat, drive the truck forward,

and then come to a stop. Leave the directional

control switch in the forward position and turn the

Keyswitch to the off position.

2.

Turn Keyswitch back to the on position and then

press on the accelerator. The truck should not move.

Cycle the directional switch to neutral and then back

to forward. The truck should now operate correctly.

3.

Next, drive the truck forward and come to a stop

leaving the directional control switch in the forward

position.

4.

Lift yourself out of the seat for three seconds. Sit

back down and then press on the accelerator. The

truck should not move without cycling the directional

switch back through neutral.

If the previous scenario is left unattended serious

damage to the mast assembly or the tilt cylinders

can occur causing extensive repair/downtime.

Do not service the side-shift bearing pads while

the Keyswitch is ON. If the control is accidently

moved serious injury could occur.

Summary of Contents for Bendi B40i4

Page 2: ......

Page 12: ...1 4 F 808 R0 FORKLIFT SAFETY AND FAMILIARITY Figure 1 2 Decals...

Page 18: ...1 10 F 808 R0 FORKLIFT SAFETY AND FAMILIARITY Table provided for general use NOTES...

Page 24: ...2 6 F 808 R0 RECEIVING AND INSPECTION Table provided for general use NOTES...

Page 54: ...4 16 F 808 R0 OPERATING THE B40I4 FORKLIFT Table provided for general use NOTES...

Page 62: ...5 8 F 808 R0 Figure 5 5 Lubrication Points...

Page 64: ...5 10 F 808 R0 Table provided for general use NOTES...