973rev401

1J534

INTRODUCTION

Your Brillion Subsoil Chisel Plow has been designed to give years of trouble-free operation. Proper care and

operation will insure the service and long life built into it.

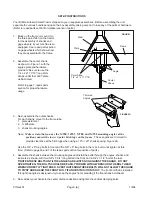

Study this manual carefully before attempting to assemble or operate the machine. When ordering parts, refer

to the model number and serial number located on the name plate on the mast at the front of the machine. (See

page 4). Please read and record these numbers upon receipt of the machine.

LOCATION REFERENCE

“Right” and “Left”, “Front” and “Rear” refer to operator’s “Right and Left”, “Front” and “Rear” when he faces in the

same direction as the machine will travel.

SAFETY

This

safety alert symbol

is used to call your attention to

instructions

concerning your personal safety.

It is found on your machine and

in this manual. It is important to pay attention the the precautions

indicated and to

be alert to the possiblility of personal injury or

death.

Federal law requires you to explain the safety and operating instructions furnished with this

machine to all employees before they are allowed to operate the machine. These instructions must

be repeated to the employees at the beginning of each season.

Be sure to observe and follow

these instructions for your own and your employee’s safety.

A subsoil chisel plow is a fairly simple machine, but it must be operated in a prudent manner.

1.

Never turn corners at a high rate of speed.

2.

Never work under the chisel plow unless it is securely blocked up and cannot be knocked off the blocks,

3.

Always take care in raising and lowering the chisel plow, and be certain that no one is in the way.

4.

Never allow passengers to ride on the chisel plow.

5.

Display the Slow Moving Vehicle emblem when traveling on roads.

6.

When traveling on the road at night, make sure that reflective decals and accessory warning lights

are mounted and visible on the machine. Local regulations should be checked first, and if there

are none, the chisel plow owner should take the initiative to make his machine noticeable at night.

Page 3

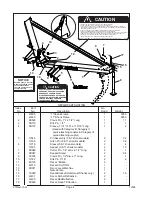

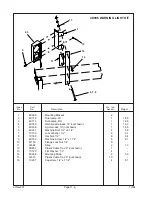

2

3

1

1

. 8J310 - Decal, “Caution” list

2. 2J431 - Decal, Reflective Amber

3. 2J430 - Decal, Reflective Red

4. 9D071- Decal, “Machine Level”

5. 8k829 - Decal, Deep Till Caution

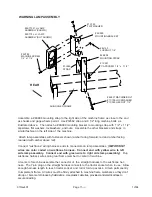

1. DO NOT LUBRICATE, ADJUST OR REPAIR WHEN MACHINE IS IN MOTION.

2. DO NOT TOW OR TRANSPORT FASTER THAN 15 MILES PER HOUR.

3. DO NOT RIDE OR ALLOW OTHERS TO RIDE ON THE MACHINE.

4. BLOCK UP ALL HYDRAULICALLY OR MECHANICALLY RAISED COMPONENTS TO

PREVENT UNINTENDED LOWERING OR LOWER THE MACHINE TO THE GROUND TO

MAKE ADJUSTMENT OR REPAIRS WHEN NOT IN USE.

5. KEEP ALL PERSONS AWAY FROM MACHINE DURING HITCHING AND OPERATING.

6. SLOW DOWN BEFORE MAKING SHARP TURNS OR USING THE BRAKES.

DRIVE SLOWLY OVER ROUGH GROUND, SIDE HILLS, AND AROUND CURVES TO AVOID TIPPING.

7. COMPLY WITH ALL LAWS WHEN TRANSPORTING THE MACHINE ON PUBLIC ROADWAYS.

8. INSTRUCT ALL OPERATORS IN THE SAFE OPERATION OF THE MACHINE.

REVIEW THE OPERATOR’S MANUAL FOR CORRECT PROCEDURES.

9. BLOCK IMPLEMENT TO PREVENT MOVEMENT WHEN UNHITCHED FROM TRACTOR.

10. KEEP ALL GUARDS AND SHIELDS IN PLACE WHILE MACHINE OR PARTS ARE IN MOTION.

8J310

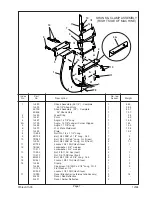

CAUTION

NOTICE

MACHINE SHOULD BE LEVEL

WHEN IN OPERATING POSITION

ADJUST UPPER LINK OF

TRACTOR 3-POINT HITCH TO

ACCOMPLISH THIS.

9D71

4

Pictured here are

the safety signs

found on your

subsoil chisel plow.

Refer to page 4 for

location on machne.

CAUTION

DEEP TILL OPERATION CAN DAMAGE

UNDERGROUND UTILITIES CAUSING

DANGEROUS CONDITIONS AND

DISRUPTING SERVICES. DETERMINE

THE DEPTH AND LOCATION OF BURIED

CABLES, PIPE LINES, AND DRAIN

TILES BEFORE OPERATION.

8K829

5

Summary of Contents for Brillion SCP-51

Page 2: ...973rev401 1J534...

Page 4: ...973rev401 1J534...

Page 12: ...973rev401 1J534 Page 8 FRONT 18 19 10 16 15 14 13 12 11 17 8 7 6 5 4 3 9 2 1...

Page 14: ...973rev401 1J534 Page 10 5 8 4 6 7 9 2 3 1 18 17 16 15 14 13 12 11 10 4...

Page 19: ...973rev401 1J534...

Page 20: ...973rev401 1J534...

Page 21: ......