973rev401

1J534

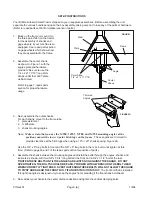

3. Next, assemble the outer shanks.

For each shank, mount to the frame tube:

1. plate weldment

2. 1J495 plate

3. shank mounting angles

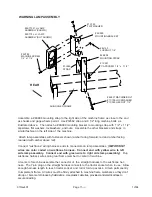

Note: Make certain that you use the

1J700, 1J701, 1J702, and 1J703

mounting angles at the

positions nearest the lower 3-point hitch lugs on the frame

. These angles are trimmed to

provide clearance at the hitch lugs when using a 19" or 20" shank spacing. Figure 2A.

Use the 3/4" x 8" long bolts in front and the 5/8" x 8" long bolts in the rear, but do not tighten at this

time. (Refer to pages 6 and 7 of the repair part section for position of parts.)

4. Assemble the shank between the mounting angles and install the bolts through the angles, shanks and

locknuts as shown, with two 5/8” x 3 3/4” long bolts at the front and a 3/4” x 3 1/2” bolt at the rear.

TIGHTEN THESE BOLTS UNTILTHE ANGLES ARE JUST SNUG AGAINST THE SHANK. DO NOT

OVERTIGHTEN. THE BOLTS SHOULD BE EASILY TURNED WITH A WRENCH ON THE BOLT HEAD

WHEN CORRECTLY TIGHTENED. OVER TIGHTENING THESE BOLTS WILL NOT ALLOW THE SHANK

TO PIVOT AND SHEAR THE FRONT BOLT IF AN OBSTRUCTION IS HIT.

The front bolt that is installed

through the angles is designed only to keep the angles from spreading if the front shank bolt shears.

5. Now, adjust your shanks to the center distance desired and tighten the vertical clamping bolts.

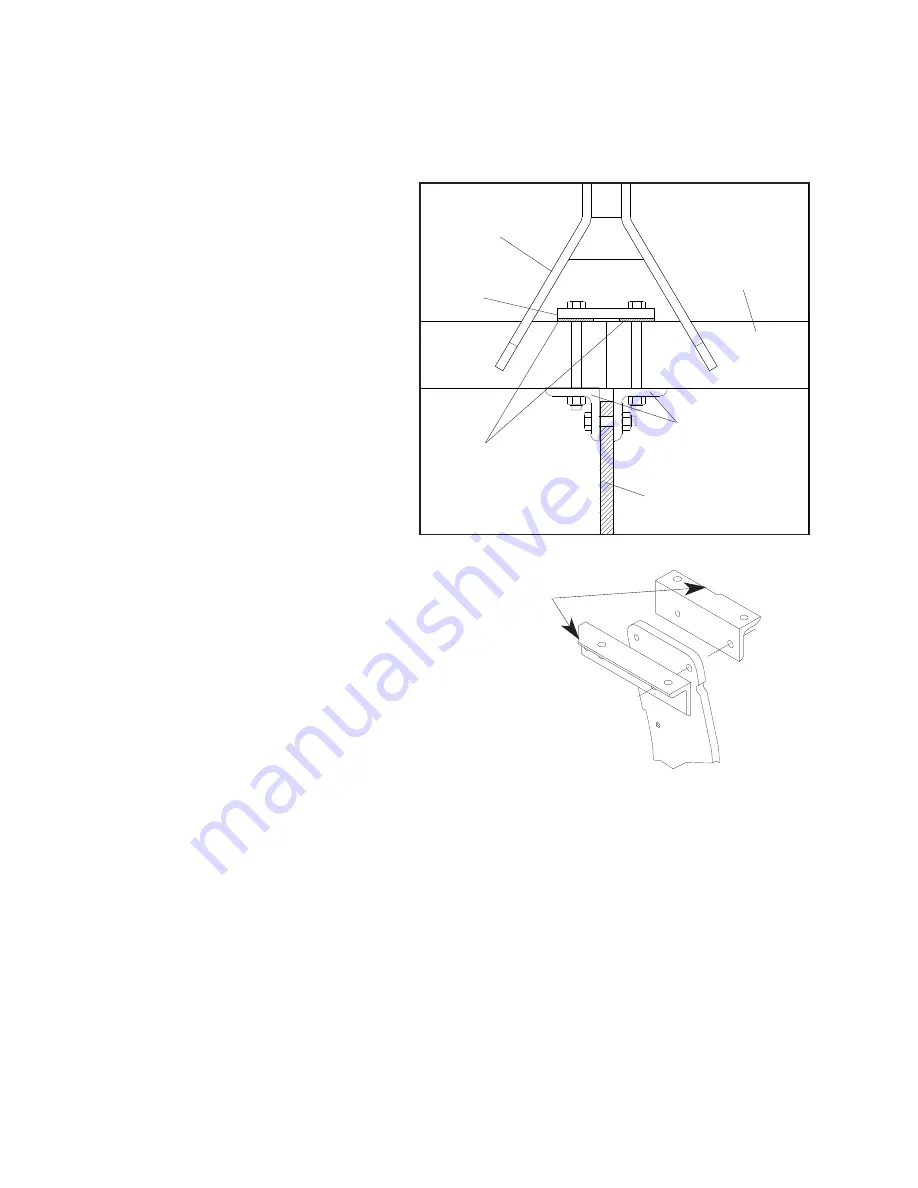

2. Assemble the center shank,

as shown in Figure 1, with the

angles, plate and hardware

provided. Be sure to use the

1/4 x 2 x 11 7/16" long shim

straps under the 1J497 plate

as illustrated.

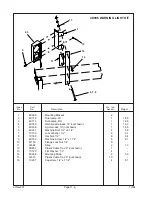

Refer to page 7, repair parts

section, for proper hardware

usage.

SET-UP INSTRUCTIONS

Your Brillion Subsoil Chisel Plow is shipped to you in separate assemblies. Before assembling the unit,

separate the various bundles and open the box assembly, taking care not to lose any of the parts or hardware.

(Refer to repair parts section for relative location of parts.)

1. Block up the frame or mount it to

the three point hitch on the tractor

for the assembly of shanks and

gage wheels, if your machine is so

equipped. See repair parts section

on gage wheels which shows how

they are assembled to the frame.

Shim Strap,

1/4” x 2” x 11 7/16”

Plate

Center

Shank

Angle

Mast

Frame

FIGURE 1

Trimmed

Angles

FIGURE 2A

Page 3-[a]

Summary of Contents for Brillion SCP-51

Page 2: ...973rev401 1J534...

Page 4: ...973rev401 1J534...

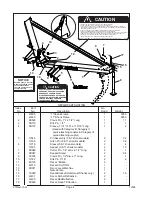

Page 12: ...973rev401 1J534 Page 8 FRONT 18 19 10 16 15 14 13 12 11 17 8 7 6 5 4 3 9 2 1...

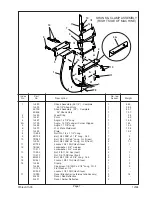

Page 14: ...973rev401 1J534 Page 10 5 8 4 6 7 9 2 3 1 18 17 16 15 14 13 12 11 10 4...

Page 19: ...973rev401 1J534...

Page 20: ...973rev401 1J534...

Page 21: ......