973rev401

1J534

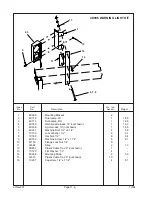

REPAIR PARTS LISTING

Index

Part

No.

No.

No. Description

Req’d

Weight

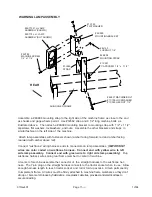

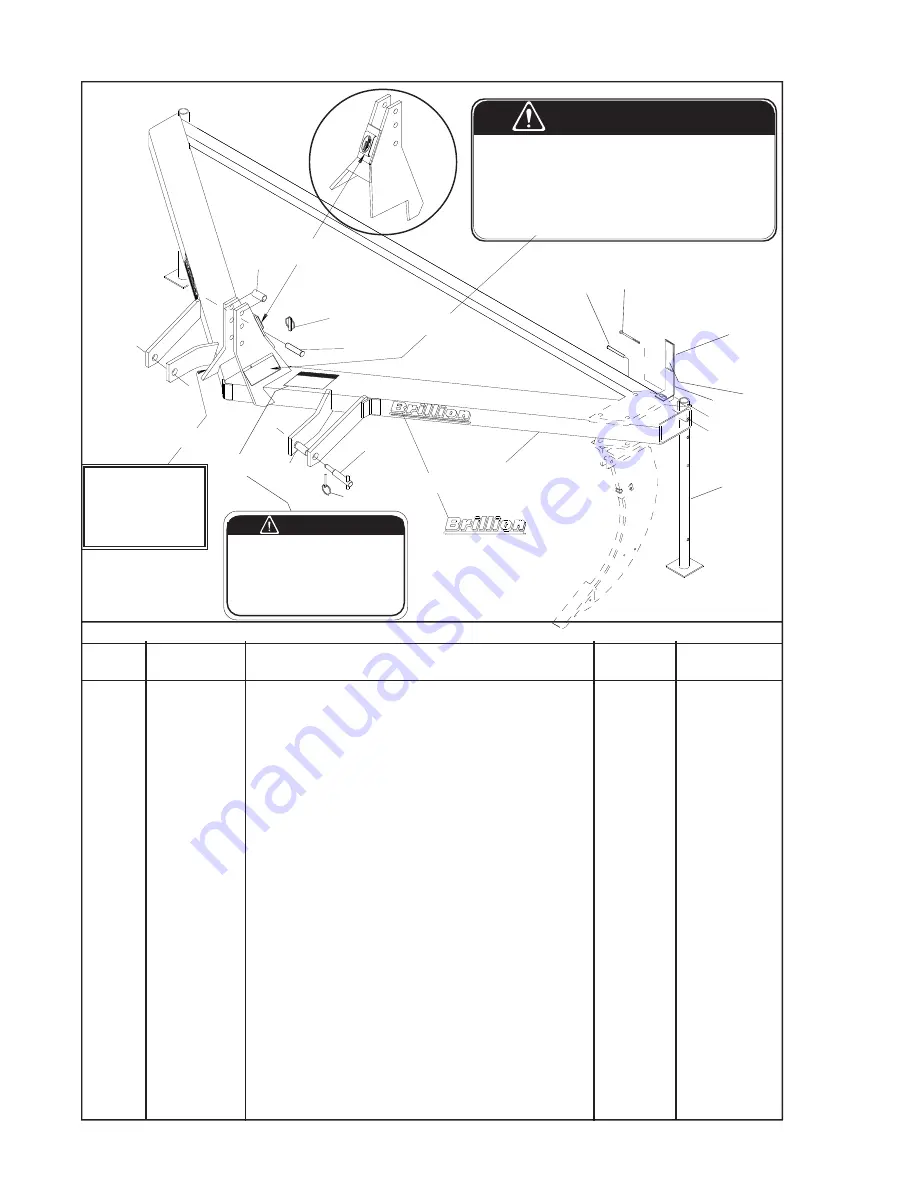

NOTICE

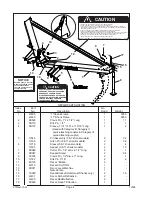

MACHINE SHOULD BE LEVEL

WHEN IN OPERATING POSITION

ADJUST UPPER LINK OF

TRACTOR 3-POINT HITCH TO

ACCOMPLISH THIS.

9D71

13

6

10

11

1

8

7

9

12

2

3

14

4

1. DO NOT LUBRICATE, ADJUST OR REPAIR WHEN MACHINE IS IN MOTION.

2. DO NOT TOW OR TRANSPORT FASTER THAN 15 MILES PER HOUR.

3. DO NOT RIDE OR ALLOW OTHERS TO RIDE ON THE MACHINE.

4. BLOCK UP ALL HYDRAULICALLY OR MECHANICALLY RAISED COMPONENTS TO PREVENT

UNINTENDED LOWERING OR LOWER THE MACHINE TO THE GROUND TO MAKE ADJUSTMENT

OR REPAIRS WHEN NOT IN USE.

5. KEEP ALL PERSONS AWAY FROM MACHINE DURING HITCHING AND OPERATING.

6. SLOW DOWN BEFORE MAKING SHARP TURNS OR USING THE BRAKES.

DRIVE SLOWLY OVER ROUGH GROUND, SIDE HILLS, AND AROUND CURVES TO AVOID TIPPING.

7. COMPLY WITH ALL LAWS WHEN TRANSPORTING THE MACHINE ON PUBLIC ROADWAYS.

8. INSTRUCT ALL OPERATORS IN THE SAFE OPERATION OF THE MACHINE.

REVIEW THE OPERATOR’S MANUAL FOR CORRECT PROCEDURES.

9. BLOCK IMPLEMENT TO PREVENT MOVEMENT WHEN UNHITCHED FROM TRACTOR.

8J310

CAUTION

5

Page 4

17

16

15

CAUTION

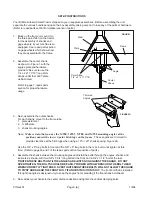

DEEP TILL OPERATION CAN DAMAGE

UNDERGROUND UTILITIES CAUSING

DANGEROUS CONDITIONS AND

DISRUPTING SERVICES. DETERMINE

THE DEPTH AND LOCATION OF BURIED

CABLES, PIPE LINES, AND DRAIN

TILES BEFORE OPERATION.

8K829

18

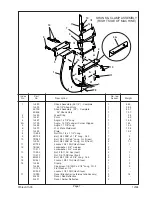

1

2J608

“7” Shank Frame

1

724.0

2J620

“11” Shank Frame

1

965.0

2

6D529

Clevis Pin, 1" x 4 1/2" Long

1

1.1

3

5D110

Klik Pin, 1/4"

1

.1

4

5D157

Sleeve, 1 1/4" O.D. x 1 15/16" Long

1

.2

(Used with Category III, Category II

quick-attaching coupler, & Category III

quick-attaching coupler)

5

1J545

Pin Assembly (5 & 7 shank models)

2

3.2

1J536

Hitch Pin (9 & 11 shank models)

2

3.6

6

1J716

Sleeve (5 & 7 shank models)

2

.4

1J535

Spacer (9 & 11 shank models)

2

1.5

7

6D049

Cotter Pin, 1/4" dia. x 2 1/2" Long

2

.1

8

9D047

Support Stand

2

9.4

9

3C335

Clevis Pin, 1/2" dia. x 3" Long

2

.1

10

1J722

Klik Pin, 7/16"

2

.2

11

4K103

Decal, “Brillion”

2

-

12

8J310

Decal, CAUTION

1

-

13

9D071

Decal, Level Machine

1

-

14

Name Plate

1

15

1K089

Decal Bracket (Outermost Shanks only)

2

1.6

16

2J431

Decal, Amber Reflective

2

-

17

2J430

Decal, Red Reflective

2

-

18

8K829

Decal, Deep Till Caution

1

-

2-10-04

Summary of Contents for Brillion SCP-51

Page 2: ...973rev401 1J534...

Page 4: ...973rev401 1J534...

Page 12: ...973rev401 1J534 Page 8 FRONT 18 19 10 16 15 14 13 12 11 17 8 7 6 5 4 3 9 2 1...

Page 14: ...973rev401 1J534 Page 10 5 8 4 6 7 9 2 3 1 18 17 16 15 14 13 12 11 10 4...

Page 19: ...973rev401 1J534...

Page 20: ...973rev401 1J534...

Page 21: ......