2-12

1P342

ASSEMBLY INSTRUCTIONS

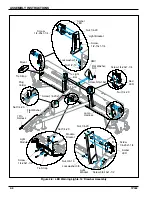

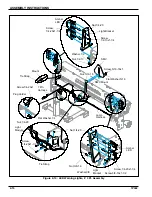

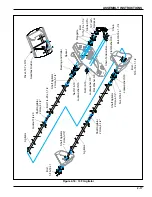

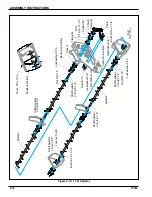

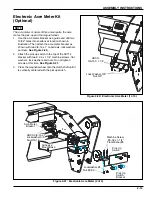

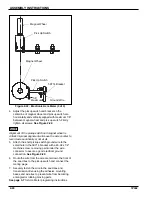

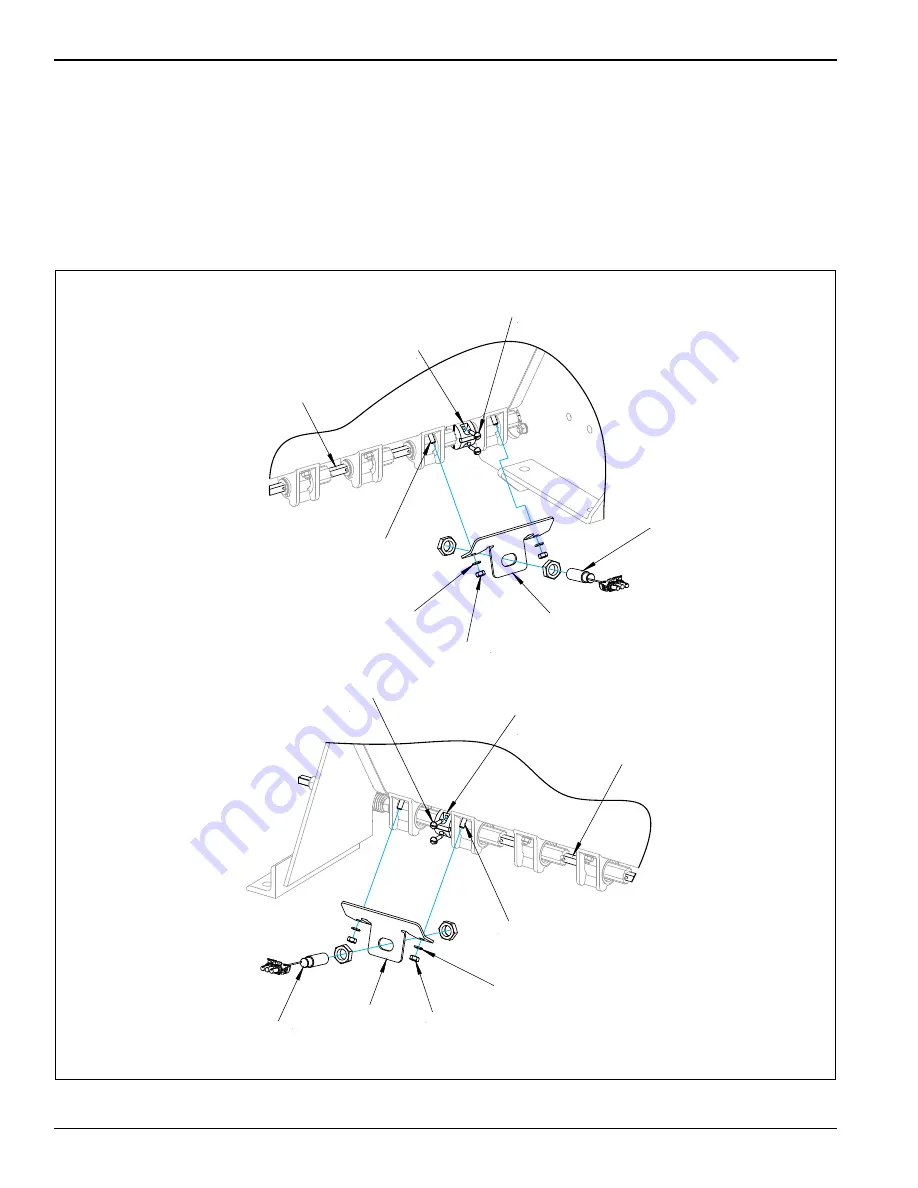

Seed Shaft Sensor Kit (Optional)

Remove the two #10 x 24 x 3/4” self tapping screws from

the Magnet Wheel Assembly. Position the rounded half of

the Magnet Wheel Assembly on the seed shaft. Ensure it

fits squarely onto shaft. Mount magnet half to the

rounded half. ensure it fits squarely onto shaft. Fasten the

two halves together using two #10-24 x 3/4” self tapping

screws.

Do not over tighten

.

Identify the seed cups on either side of the Magnet

Wheel Assembly and remove the 1/4-20 hardware. Insert

Sensor into Shaft Sensor Bracket slot.

Insert a 1/4-20 x 3/4” machine screw into each seed cup.

Align the Shaft Sensor Bracket with the two 1/4-20 x 3/4”

screws. Secure with existing lockwashers and nuts.

Slide/Position Seed Shaft Sensor so it is 1/8” from the

magnet.

Figure 2-12: Seed Box Brackets

Seed Shaft

Magnet Wheel

Assembly

3/8 Sq Shaft

Screw,Self Tapping

#10-24 x 3/4

Existing

Nut,1/4-20

Shaft Sensor

Bracket

Seed Shaft

Sensor

Existing

Lockwasher,1/4

Machine Screw,

1/4-20 x 3/4

Screw,Self Tapping

#10-24 x 3/4

Seed Shaft

Magnet Wheel

Assembly

3/8 Sq Shaft

Machine Screw,

1/4-20 x 3/4

Existing

Lockwasher,1/4-20

Existing

Nut,1/4-20

Shaft Sensor

Bracket

Seed Shaft

Sensor

MidBoxSensorBrkts

Summary of Contents for BRILLION SL Series

Page 2: ......

Page 9: ...SAFETY INFORMATION 1 5 Decals Figure 1 3 8 Ft Model Decals 1 1 2 10 11 5 5 6 3 4 3 4 8 8 7 9...

Page 10: ...1 6 1P342 SAFETY INFORMATION Figure 1 4 10 Ft Model Decals 10 11 1 2 5 5 6 3 4 3 4 7 8 8 1 9...

Page 11: ...SAFETY INFORMATION 1 7 Figure 1 5 12 Ft Model Decals 11 2 1 10 3 4 5 5 6 3 4 9 8 1 7 8...

Page 12: ...1 8 1P342 SAFETY INFORMATION Figure 1 6 Hitch Decals 12 13...

Page 14: ...1 10 1P342 SAFETY INFORMATION Table provided for general use NOTES...

Page 21: ...ASSEMBLY INSTRUCTIONS 2 7 Table provided for general use NOTES...

Page 40: ...2 26 1P342 ASSEMBLY INSTRUCTIONS Table provided for general use NOTES...