2-18

1P124-2306

Brillion Elite Mini Monitor -

Optional

IMPORTANT

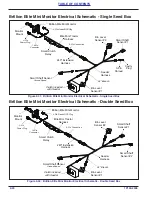

The Brillion Elite Mini Monitor System by Loup

utilizes a MUX communication line. Sensors must be

learned into the Monitor. Location of each pre-learned

Smart Shaft Sensor or Bin Level Sensor is important

for proper Monitor display. Each Sensor utilizes 3

wires (+, -, MuxBus) to connect to the system. The

Sensors do not require specific Harness connection

points. Each Sensor is identified in the Monitor by its

own signal.

WARNING

IMPORTANT

All Harnesses must be firmly attached to Machine

Frame members so they do not sag or become torn

loose by field debris.

Refer to Brillion Elite Mini Monitor Single or Double Box

Electrical Schematic.

and

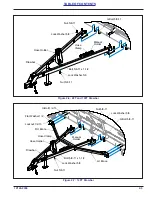

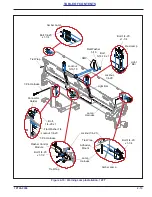

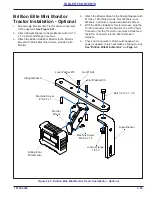

1. Lay out the Seeder Harness on the front of the Seeder

ensuring that the Electric Clutch 2-Pin Connector is

on the left side. The Seeder Harness 24" Branch

connects to the LH Bin Level Sensor.

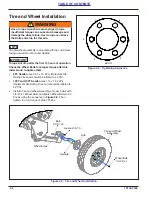

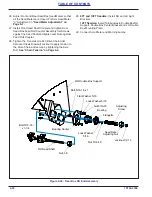

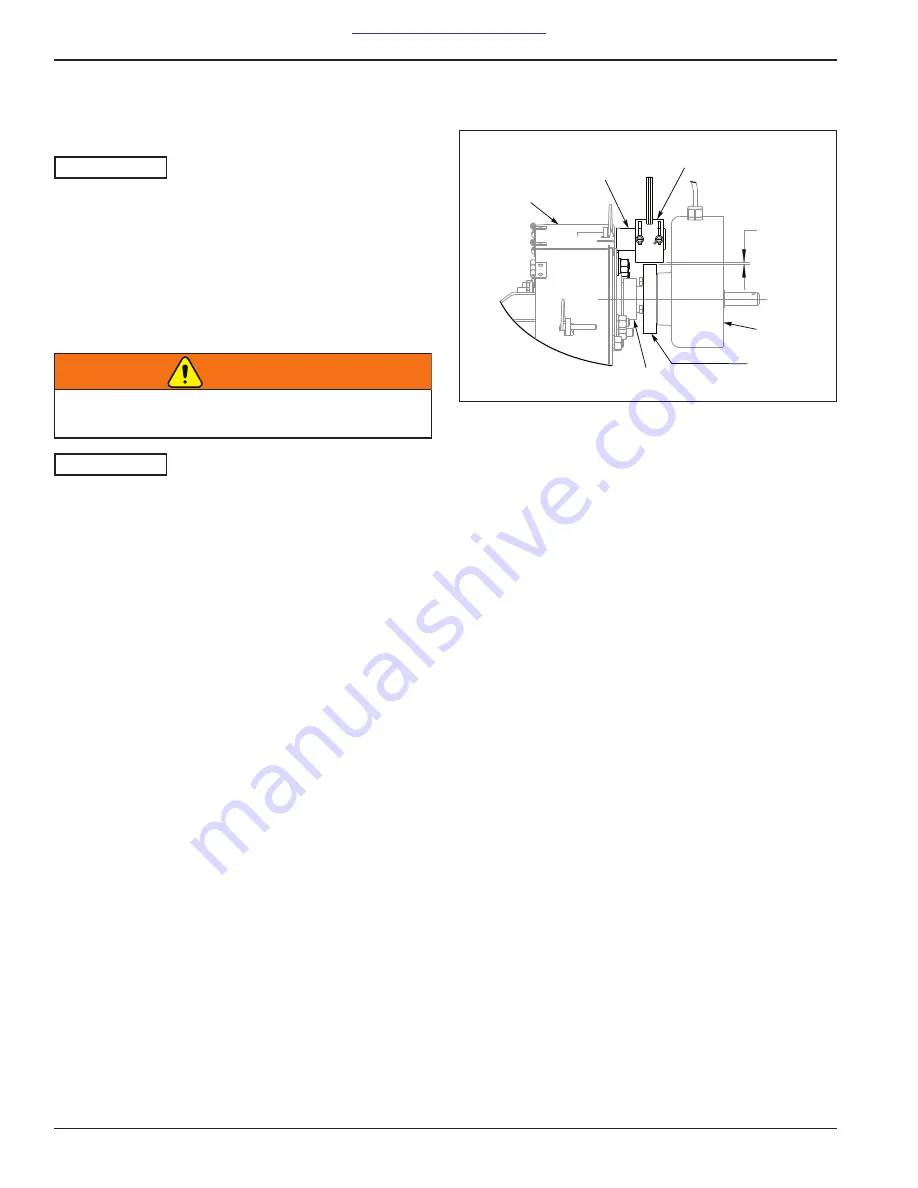

2. Remove Seeder Clutch. Install Actuator Assembly

onto the Quill Shaft outer diameter, securing with

Actuator Assembly Set Screw. Reinstall Clutch.

Install Pick-up Switch Bracket to the

Transmission Input Shaft Bearing Flangette Hardware.

Assemble Smart Shaft Sensor onto the Pick-Up Switch

Bracket with sensor provided hardware and #8-32

Flange Locknuts. Adjust the Smart Shaft Sensor so

that it is 1/8" Max away from the Actuator Assembly.

Connect Ground Speed Smart Shaft

Sensor to the Center Seeder Harness.

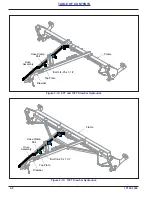

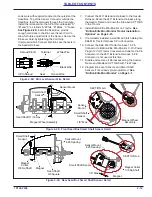

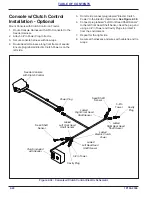

3. Front RH side Seed Box between the 2nd and 3rd

Seed Meters, install Magnet Wheel Assembly on the

Hex Seed Shaft.

Remove the 3rd

and 4th Seed Meter front Round Head Machine

Screws that mount the Seed Meter to the Seed Box

and replace them with 1/4-20 x 1 Round Head

Machine Screws. Install the Sensor Mount on the

1/4-20 x 1 Machine Screws. Secure with Flat

Washers, Lock Washers and Nuts. Install a Smart

Shaft Sensor to the Sensor Mount with sensor

provided hardware and #8-32 Flange Locknuts.

Adjust the Smart Shaft Sensor so that it is 1/8" Max

away from the Magnet Wheel Assembly on the Seed

Shaft.

Connect the Smart Seed

Shaft Sensor to the Seeder Harness.

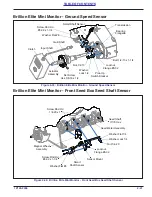

Figure 2-27: Ground Speed Sensor Detail

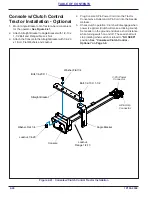

4. If equipped with a Rear Seed Box, removed the RH

Rear Deflector and replace it with notched RH Rear

Deflector which allows access to the Smart Shaft

Sensor.

between the 2nd and 3rd Seed Meters, place 1-1/4 x

1/4 x 1/16 Magnet on the Seed Shaft. Secure with

Magnet Collar. Remove the 1st and 2nd Seed Meter

rear Round Head Machine Screws that mount the

Seed Meter to the Seed Box and replace them with

1/4-20 x 3/4 Round Head Machine Screws. Install the

Sensor Mount on the 1/4-20 x 3/4 Machine Screws.

Secure with Flat Washers, Lock Washers and Nuts.

Install a Smart Shaft Sensor to the Sensor Mount with

sensor provided hardware and #8-32 Flange

Locknuts. Adjust the Smart Shaft Sensor so that it is

1/8" Max away from the Magnet Collar on the Seed

Shaft.

Shaft Sensor to the Seeder Harness.

5. In not equipped with a Rear Seed Box, seal the

Seeder Harness Connector with a 3-Pin Shroud and

Cavity Plugs to protect the Harness from the

environment.

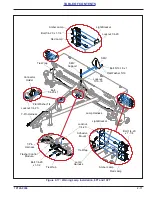

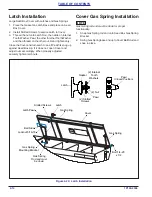

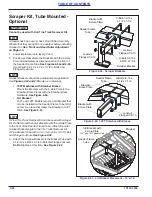

6. The Seeder RH and LH ends only, remove the .803

Knockouts in the Seed Box.

Do Not remove the

Knockouts in the Seed Boxes at the center of the

Seeder.

7. On the inside at either end of the Seed Box, install a

Bin Level Sensor Bracket with the Seed Box Mounting

3/8-16 Hardware.

Determine the

desired level for the alarm to be indicated on the

Brillion Elite Mini Monitor and assemble the Bin Level

Sensors to Bin Level Sensor Brackets with sensor

provided hardware and #8-32 Flange Locknuts. If more

adjustment is needed, the Bin Level Sensor Brackets

can also be raised or lowered to the desired seed level.

Install Cord Grips from the inside of the Seed Box out

High Power Magnet is use. See “High Power

Magnet” on Page 1-2.

1/8"

Max

Pick-Up Switch

Bracket

Smart Shaft

Sensor

Actuator

Assembly

Clutch

Transmission

Bearing

Summary of Contents for Brillion Turfmaker III Series

Page 4: ......

Page 14: ...1 6 1P124 2306 TABLE OF CONTENTS Figure 1 4 Decal Placement Hitch SL2 HitchDecals 1 9 1 9 3...

Page 18: ...1 10 1P124 2306 TABLE OF CONTENTS Table provided for general use NOTES...

Page 45: ...1P124 2306 2 27 TABLE OF CONTENTS Table provided for general use NOTES...

Page 49: ...1P124 2306 2 31 TABLE OF CONTENTS Table provided for general use NOTES...

Page 57: ...1P124 2306 2 39 TABLE OF CONTENTS Table provided for general use NOTES...

Page 74: ...3 14 1P124 2306 TABLE OF CONTENTS Table provided for general use NOTES...

Page 102: ...6 4 1P124 2306 TABLE OF CONTENTS Table provided for general use NOTES...