3-2

F-459-R1

HYDRAULIC OIL, MOTORS, PUMPS AND CYLINDERS

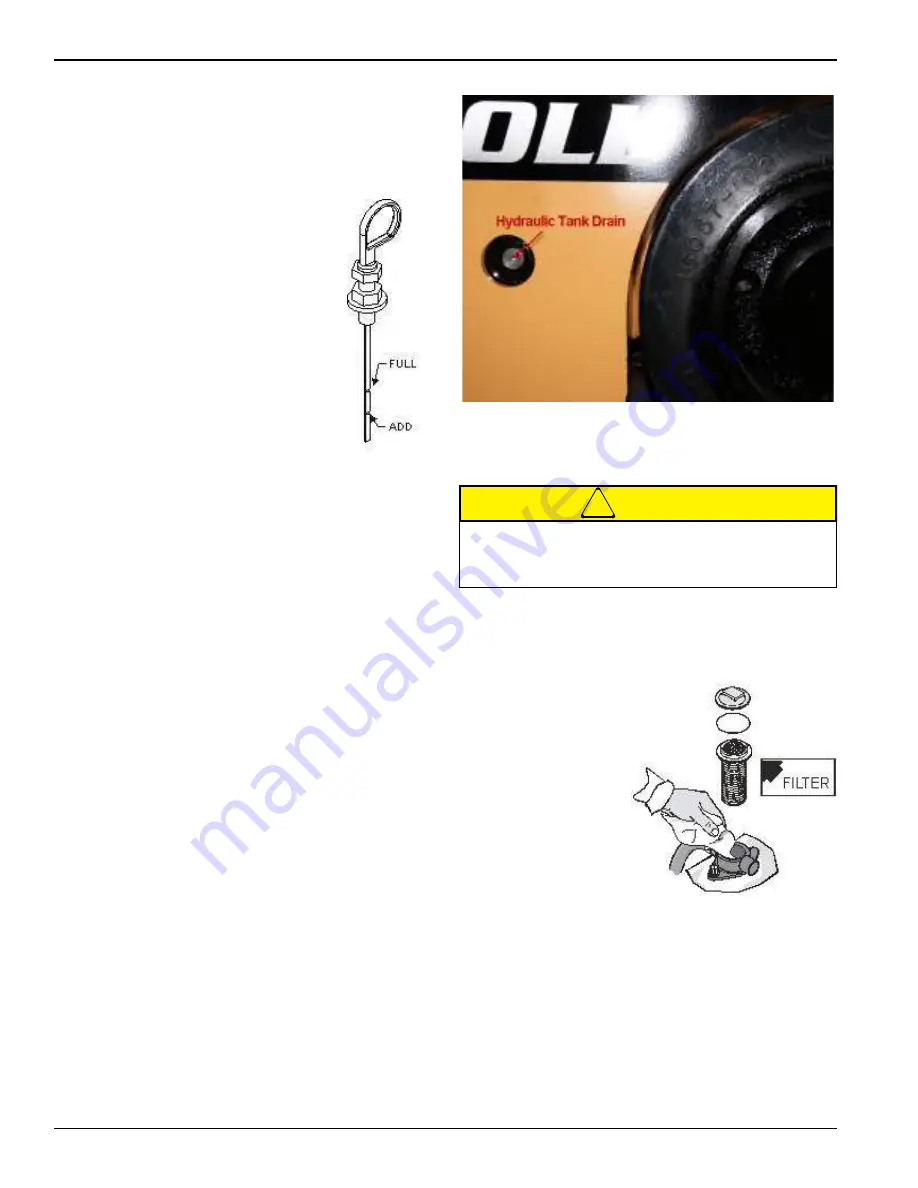

1.

Lower the mast to the floor, then tilt it back

completely.

2. Turn the key switch to OFF, remove the hydraulic tank

access cover.

3.

Remove the dipstick, holding the dipstick tip level,

check the oil level. If the oil level is at

the FULL line or between the FULL

and ADD lines, the level is correct and

no oil is needed. If the oil is at or below

the ADD line, you will need to add oil to

bring it up to the FULL line (maximum).

4.

Add hydraulic oil as needed. See

page 1-7 for hydraulic oil

specifications.

5.

If the fluid appears very dirty or dark in

color, check the truck’s maintenance

log for the last fluid and filter change,

and change accordingly.

6.

Install dipstick, making sure it is

seated.

7.

Install the hydraulic access cover.

Changing Hydraulic Oil

1.

Park the truck on a level, designated service area.

2.

Block the front wheels.

3.

Perform Lock Out/Tag Out procedure.

4.

Set the key to OFF, remove the key from the key

switch and place in a secure area.

5.

Disconnect the battery.

6.

Remove the hydraulic access cover.

7.

Open the fill/dipstick cap.

8. The hydraulic reservoir drain plug is located in the

right side of the truck, as shown in figure 3-1 photo.

9.

Slide a flat collection pan, (minimum 10 gallons - 40

liters) under the drain plug, then remove the plug.

10. Change the hydraulic filter. See “Change the

Hydraulic Oil Filter”.

11. Clean the magnetic trap on the drain plug of any

contaminants. When the tank is empty, clean and

reinstall the drain plug.

12. Add hydraulic oil. See page 1-12 for recommended

lubricants. DO NOT overfill.

13. Replace the fill/cap, turn clockwise and make sure it

is tightened securely.

14. Make sure the drain plug is tight enough to prevent

oil leaks, but do not over tighten.

15. Run lift to check for leaks.

16. With the lift OFF and the forks down, check the oil

level on the dipstick and add oil accordingly.

Figure 3-1: Hydraulic Tank Drain

Change the Hydraulic Oil Filter

CAUTION

1.

Park the truck on a level, designated service area

and block the wheels.

2.

Set the key to OFF, remove the key from the key

switch and place in

a secure area.

3.

Perform Lock

Out/Tag Out

procedure.

4.

Disconnect the

battery.

5.

Remove the access

cover.

6.

Using a clean,

lint-free cloth, clean

the area around the

filter element

housing.

7.

Unscrew oil filter cap and pull the filter element from

the tank.

8.

Install the new filter element and tighten fill cap.

9.

Operate the hydraulic system by running the mast

functions and observe the filter for oil leaks.

10. Reinstall the access cover.

After prolonged truck use, hydraulic oil will be

hot and can burn human skin. Allow hydraulic oil

to cool before performing this procedure.

https://www.forkliftpdfmanuals.com/