Operation & Maintenance Manual

19

COMMISSIONING

3. Trap the key in PE lock provided at BUS Copler panel and

move DS of BUS Coupler to Earth postion.

4. Earth BUS-B by making DS Riser and breaker of BUS coupler

ON.

3. PROOF OF EARTH

Feeder: Incomer & Outgoing Panels

Proof of Earth (POE)

1. In normal condition key will be trapped in POE lock located at

DS mechanism.

2. Key shall be available free only when DS in Earthed.

3. DS can not be operated from Earth position, till Key is inserted

in lock.

Sequence of operation to open cable compartment cover

person

1. After Earthing cable, take out key from POE lock located at

DS mechanism.

2. This POE key can be used to open power cable compartment.

3. Key will be trapped in lock provided for opening power cable

compartment cover till it is open.

4. Key will be available free only after closing cable

compartment with its cover.

4. CABLE ACCESS

The opening of cable access cover is not possible unless the

cable have been connected to EARTH .

Isolator operation is not possible if the cable access cover is

OPEN .

Padlocking Facility :-

1. Metering & DS mechanism compartment door handle.

2. VCB compartment door handle.

3. Aux./ front cable entry compartment door handle.

4. DS operating hole pad loack.

Visual Indications :-

1. ON & OFF status of VCB.

2. ON , OFF & EARTH status of Disconnector Switch.

3. Operation counter (5digit) on VCB front facia.

4. Spring Charged/Discharged indication ag on VCB front

facia.

5. SF6 Gas pressure monitoring device on VCB compartment

door facia for VCB & DS compartment tank.

6. SF6 Gas pressure monitoring device on Metering & DS

mechanism compartment door facia for busbar chamber

tank. This device is provided in any one panel of the

board as bus bar chamber tank is common.

Optional Interlock and Visual Indication :-

Following Optional interlocks can be provided :-

1. M.I.L. solenoid interlock is provided to prevent opening of

rear cable cover.

2. VCB is tripped electrically if SF6 Gas pressure falls below

the minimum permissible value i.e., 1.2 bars.

3. Semaphore indication is provided.

4. For any special key interlock please refer key interlock

arrangement provided by Design.

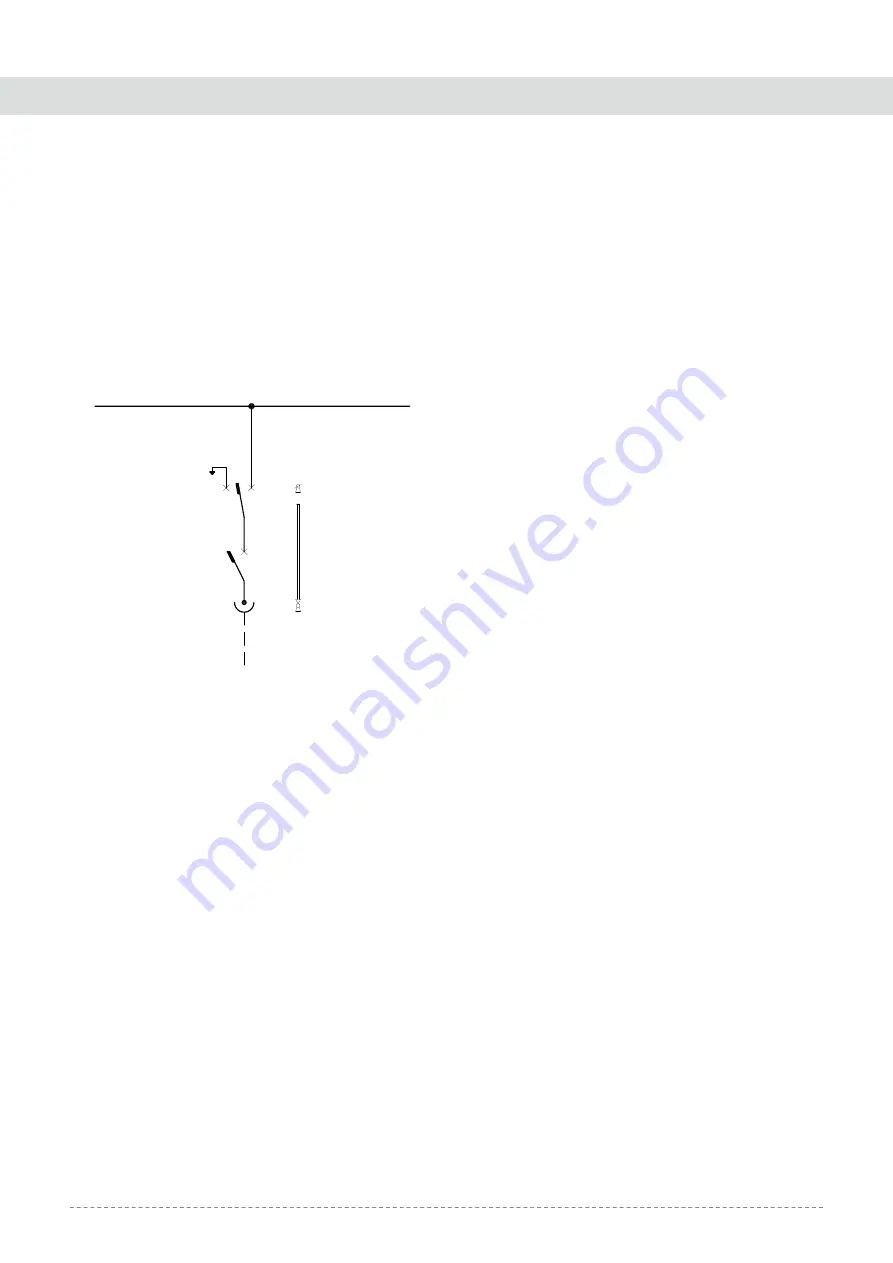

Figure 6.4.6 - Incomer & Outgoing Panels

Lock & Key Qty Details

POE: 2 Lock & 1 Key

Q1

DISCONNECTOR

SWITCH

1250A

Q0

VCB

1250A

EAR

TH

OFF

ON

POE

POE