VACUUM CIRCUIT BREAKER

Operation & Maintenance Manual

03

The type GV3N-CB are tested as per IEC. They have been

designed for reliability with minimal maintenance so that there is

no need for access into the SF6 insulated chambers during the

life of the vacuum interrupter. The motor wound stored energy

spring mechanism has been designed with a minimum number

of high quality components in line with this concept.

The mechanism and drive is bolted out side of the circuit breaker

tank and the three pole assemblies are bolted inside SF6 tank.

They are connected via contact wipe springs and coupling rods

through gas tight sealing bushes to the insulators xed to the

vacuum interrupter moving terminals. The sealing ring is

mounted in the brass hub on the tank.

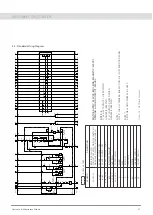

3.1 - Pole Assembly

The vacuum interrupter is xed to its cast resin insulation

supports by a connection plate attached to the xed terminal.

The mechanism end of the assembly is tied together by the

molding mounting plate which located around the seal bush.

The phase assembly is xture built to ensure the correct lineup of

interrupter, current transfer contact from interrupter moving

terminal and the drive through the sealing bush. Thus when an

interrupter reaches the end of its life, the complete pole

assembly is replaced.

3.1.1 - Closing of Interrupter Contacts

The discharging of the mechanism closing spring rotates the

secondary shaft anti-clockwise to push the interrupter contacts

to the contact touch point via the pre-stressed contact spring

and the coupling rods. The coupling rods stop moving at this

point but the mechanism continues to further compress the

contact spring opening up the wipe or snatch gap until the

mechanism latches and the circuit breaker pole is then

considered closed. This closing movement also charges the pre-

loaded opening springs.

3.1.2 - Opening of the Interrupter Contacts

The displacement of the mechanism trip latch allows the

opening springs and the contact springs to rotate the secondary

shaft clockwise until the wipe or snatch gaps are zero. This is the

point of contact separation and from this point the momentum

and the continuing action of the opening springs alone pull the

coupling rods and thus the interrupter contacts to the fully open

position.

3.0 VACUUM CIRCUIT BREAKER

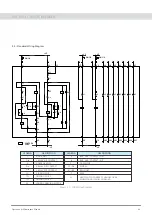

3.2 - Vacuum Circuit Breaker Operating Mechanism

The mechanism is of the stored energy, motor wound or

manually charged spring operated type. It is suitable for auto-

reclosing duties. Basically it comprises a closing spring charging

system and a spring charged latch, a closing cam, the close / trip

latch which is displaced to trip the closed circuit breaker, and the

drive to the poles in the form of the secondary shaft. In addition

there are the spring release solenoid, the trip solenoid, the

auxiliary switches and manual operation On-Off push buttons.

3.2.1 - Motor Charging Mechanism

The closing springs are charged electrically by the motor and

gearbox rotating the mechanism main drive shaft via the pawl

drive arm and ratchet plate. The rollers mounted each side of the

ratchet plate engage with the closing spring latch after passing

through

top dead centre . Reverse movement of the

mechanism shaft is prevented by a clutch mounted in the

mechanism side sheet. The design of the ratchet plate prevents

overcharging by means of a non-toothed area. An additional

cam on the main shaft operates a limit switch which opens the

motor circuit and completes the spring release solenoid circuit.

When the closing spring is discharged, the limit switch condition

is reversed and the motor recharges the closing spring

automatically.

3.2.2 - Manual (emergency) Charging

The closing spring is tensioned manually by tting the hand

crank lever onto the intermediate shaft on the motor gearbox.

This handle is tted with a clutch to prevent reverse movement.

3.2.3 - Closing

When the closing spring is CHARGED and the circuit breaker

indicates Open , the circuit breaker can be closed by either the

electrical release of the closing spring or by the manual close

pushbutton. This causes the main shaft and thus the drive cam

to rotate driving the secondary shaft anti-clockwise via the roller.

When the circuit breaker is fully closed, the close/trip latch

locates behind the roller holding the circuit breaker closed and

indicating Close .