Operation & Maintenance Manual

06

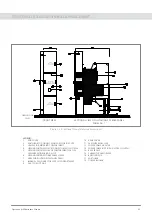

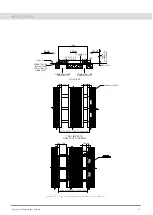

STRUCTURAL DETAILS & GENERAL ARRANGEMENT

panel may start dropping and may fall to 1.25 bar. In this case

the operator needs to shutdown the panel and has to check it

for leakage. Once the leakage is identi ed and is welded, air is

lled in the panel to check, if the weld has removed the leakage

and there is no further leakage, after which the SF6 gas is lled

in the equipment at a desired pressure of 1.35 bar. The detailed

procedure for Vacuuming and Gas

lling is provided in

Annexure-A. After the gas lling is completed the Power

Frequency Withstand Test should be done at sight.

Note:

For quality and purity of SF6 gas refer the quality

certi cates of the producers and manufacturers of SF6.