OMG200N1.23

G200 Analyser Range

Page

20

©

Copyright 2010 Geotechnical Instruments (UK) Limited

Soft-Keys:

Delete - Enables the operator to backspace delete digits keyed in the ‘Enter Site’ field.

Find - Enables the operator to search and find pre-stored IDs.

Exit

- Enables the operator to exit the ‘Enter Site ID’ screen and return to the ‘Main

Read Screen’.

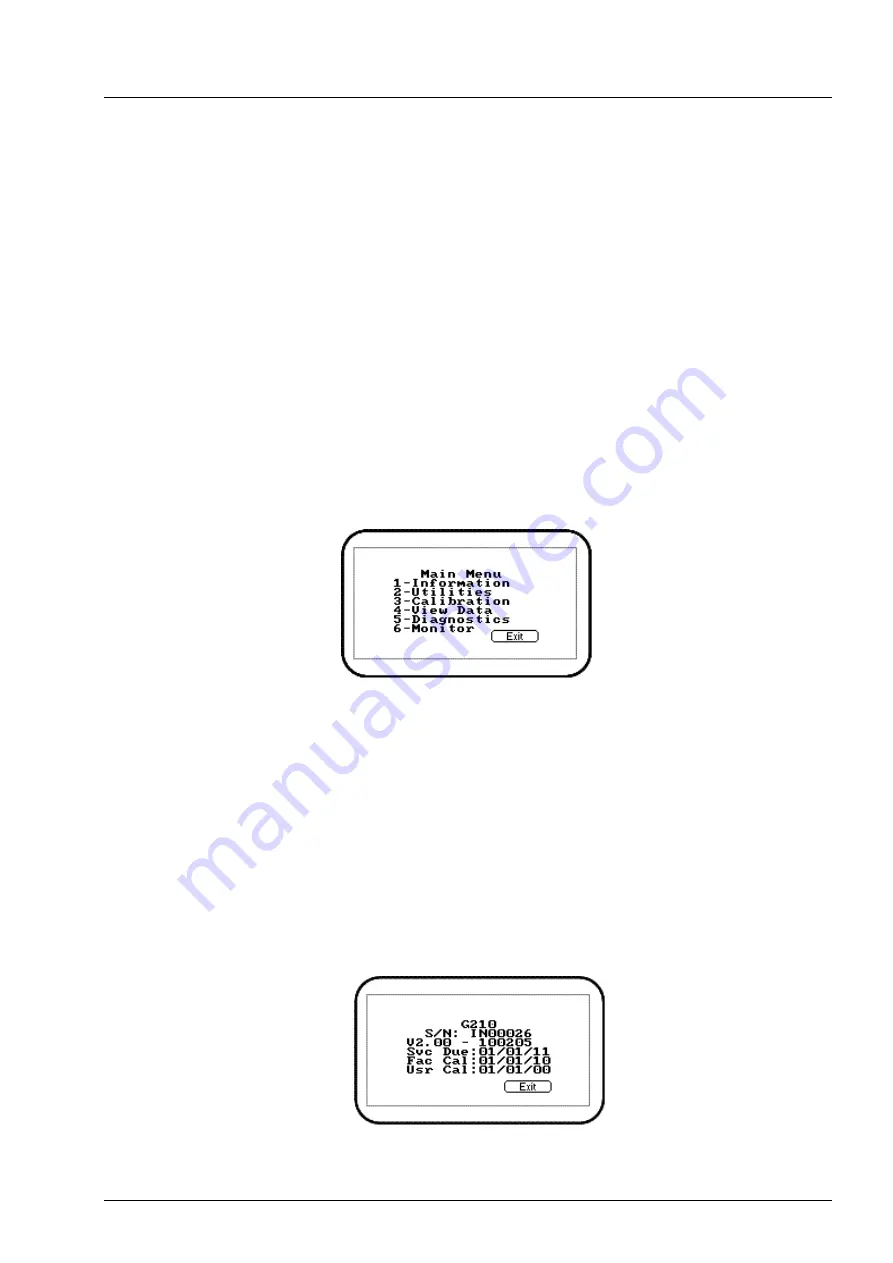

5.12 Main Menu

The ‘Main Menu’ enables the operator to select options to set up specific parameters and

perform operational tasks prior to sample readings being taken or to view data and

information stored in the instrument.

"

Note: Unless otherwise stated the functions and menus are the same for both the G200

and G210 instrument.

1)

Press the ‘Menu’ key on the front of the instrument panel and the following screen is

displayed:

Main Menu

2)

Press the soft-key ‘Exit’ to exit the ‘Main’ menu.

5.12.1 Information

The ‘Information’ option enables the operator to display information such as instrument

type, serial number, current software version, service due date and the dates of the last

factory and user calibrations.

1)

From the ‘Main Read Screen’ press the ‘Menu’ key on the instrument panel.

2)

Press ‘Key 1’ to display general information about the instrument.

Information Screen