G200 Analyser Range

OMG200N1.23

©

Copyright 2010 Geotechnical Instruments (UK) Limited

Page

37

open regulator valve to allow the gas to flow.

2)

Press the ‘Start’ key and wait for the reading to stabilise. This can take a couple of

minutes. Press the ‘Pump’ key to draw sample gas.

3)

Once a stable reading is shown press the soft-key ‘Accept’. A successful span

calibration message will then be displayed. Press the soft-key ‘Accept’ again to

confirm the calibration and ‘Store’ the new user span. Alternatively, press soft-key

‘Reject’ to exit without change.

"

Note:

If the calibration failed then try again using a longer purge time or different

target gas.

7.5.3 Reset Factory Settings

This option will reset the instrument to its factory programmed calibration characteristics

and will clear the user calibration points for both gas channels.

1)

To reset to factory settings, press ‘Key 1 - Factory Reset’ from the ‘Calibration’

menu.

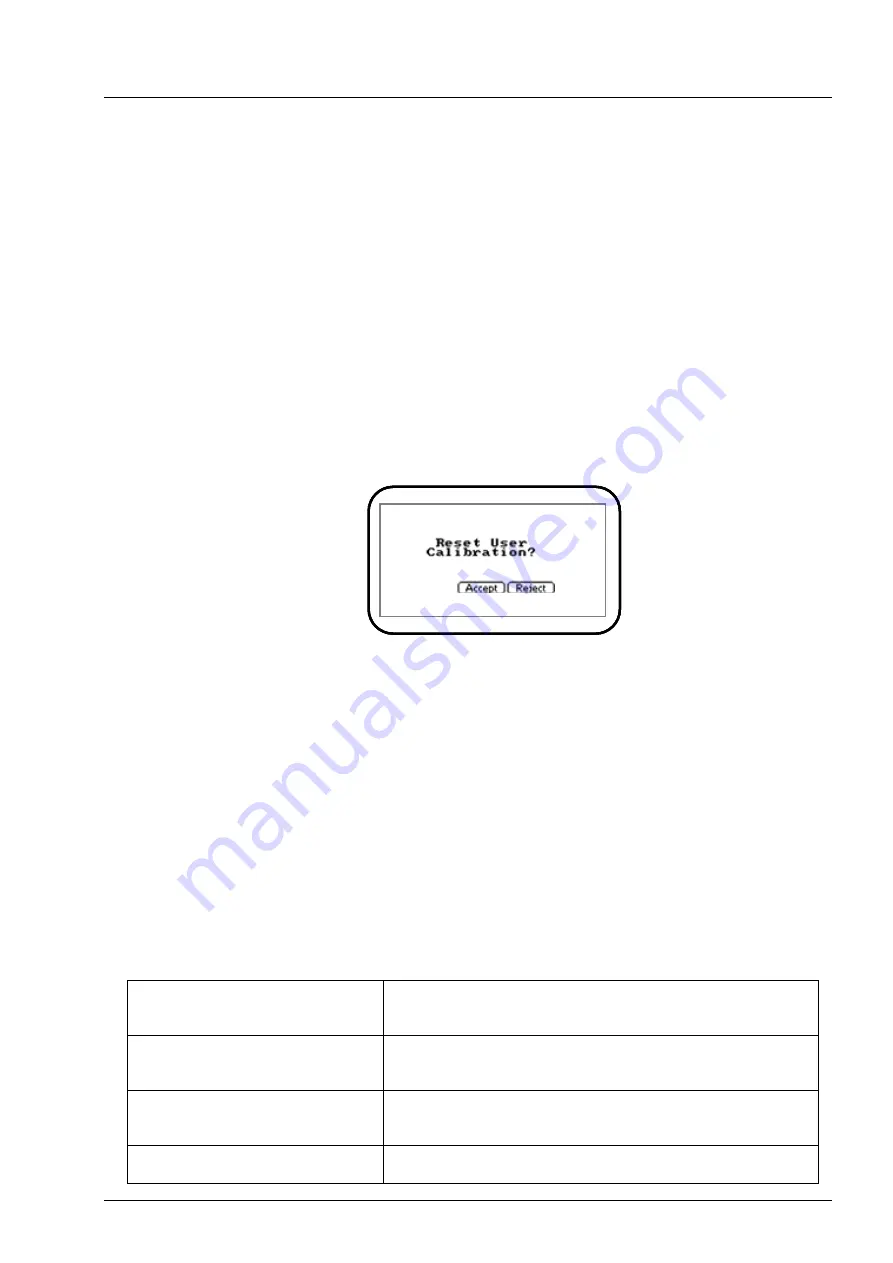

User Calibration - Reset

2)

To prevent the user calibration data being accidentally erased the user must confirm

the action by pressing the soft-key ‘Accept’, or soft-key ‘Reject’ to exit without

change.

7.6 Last Field Calibration

This data can be found in the ‘Information’ screen accessed via the ‘Utilities’ menu. This

option displays the date that the last field calibration was performed on the instrument.

7.7 Calibration Record

The G200 instruments have the facility to log user calibrations via the ‘Event Log’. This can

be used as an aid in ensuring that gas measurements are valid and accurate.

During calibration the instrument will record the following in the event log. For each entry

the time and date will be stored.

Event

Data Recorded

Successful user zero

for

selected gas

Type (N

2

or Air) and Readings before and after

Successful user span for

selected gas

Target Value, Readings before and after

Successful user span for

selected gas

Target Value, Readings before and after