Page A - 27

A

LW SC-300 E / LW SC-350 E

Version: 06.12.2022

F I R S T C O M M I S S I O N I N G

Check oil level

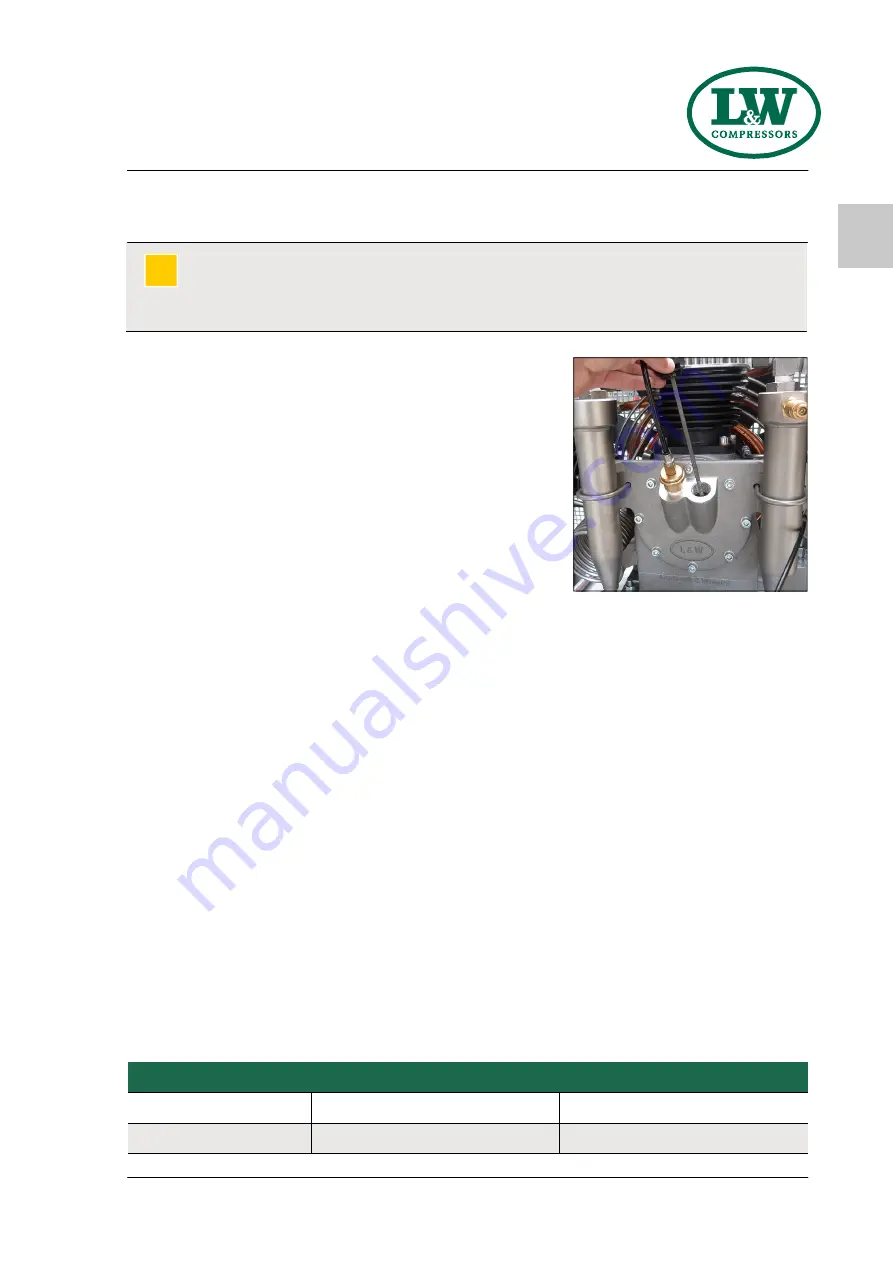

Check the oil level before each operation of the unit by using

the oil dipstick.

Oil level check as follows:

• Unscrew oil dipstick

• Wipe off oil residues

• Insert the oil dipstick back into its tube and screw it until

stop

• Unscrew oil dipstick again

The oil level should be between the notch and the end of the

oil dipstick. If there is no oil between the notch and the end

of the oil dipstick, refill immediately new full synthetic

compressor oil.

Warning

Check oil level daily. Never start the compressor with a too low oil level. Risk of accidental

loss, destruction or deterioration.

!

Check V-belt tension

The V-belts could lose tension during transportation. Please check the V-belt tension before starting

the compressor.

Tension V-belts

To tighten V-belt tension, loosen 4 mounting nuts of the drive motor. Use the tensioning screw to

move the electric motor until the V-belt tension is sufficient. Then, tighten mounting nuts and check

V-belt tension.

We recommend using a V-belt tension gauge.

Correct V-belt tension

Do not tension V-belts too tight. This damages bearings of compressor and motor. The V-belts

should only be tensioned until there is no noise caused by slipping during start.

Motor Type

Initial Installation

Operation after running in

Electric motors 50Hz

500 N

400 N

Electric motors 60Hz

400 N

300 N

Settings

Oil dipstick

Summary of Contents for SC-300 E

Page 3: ...A Operating Instructions Breathing Air Compressor LW SC 300 E LW SC 350 E Version 12 22 E...

Page 12: ...A S A F E T Y P R E C A U T I O N S...

Page 19: ...A I N S TA L L AT I O N...

Page 26: ...A O P E R AT I O N...

Page 34: ...A R E M E D Y I N G FA U LT S...

Page 39: ...A M A I N T E N A N C E A N D S E R V I C E...

Page 67: ...A M A I N T E N A N C E R E C O R D S...

Page 75: ...E A T T A C H M E N T Version 11 12 E...

Page 79: ...INFORMATIONON THE SERVICE LIFE OF L W HIGH PRESSURE HOSES...

Page 87: ...ANNEX...