Page A - 56

A

LW SC-300 E / LW SC-350 E

Version: 06.12.2022

M A I N T E N A N C E A N D S E R V I C E

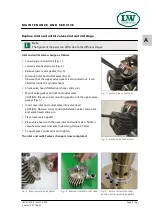

Cylinder heads and valves

Inlet and outlet valves of the specific compressor stages are

located between valve head and cylinder. Outlet valves open

while piston upstroke or compression stroke, inlet valves

open while downstroke.

Valves are subject to normal wear and tear and have to be

replaced at certain intervals (depending on specific operating

conditions). Dismount valve heads to change valves. The

three valves are combined inlet and outlet valves. The first

stage is a plate valve. The stages two and three are made of

a spring operated piston which acts inside a bronze cylinder.

Maintenance intervals

All valves should be replaced after 2000 working hours due to normal wear and tear. To replace

valves the cylinder heads have to be removed. There are no special tools required to replace these

valves.

Available special tools

Special tools are not necessary for dismounting inlet and

outlet valves but make work easier.

Order number: 006847

Special tool

Inlet and outlet valve incl. gaskets of the

3rd stage

Summary of Contents for SC-300 E

Page 3: ...A Operating Instructions Breathing Air Compressor LW SC 300 E LW SC 350 E Version 12 22 E...

Page 12: ...A S A F E T Y P R E C A U T I O N S...

Page 19: ...A I N S TA L L AT I O N...

Page 26: ...A O P E R AT I O N...

Page 34: ...A R E M E D Y I N G FA U LT S...

Page 39: ...A M A I N T E N A N C E A N D S E R V I C E...

Page 67: ...A M A I N T E N A N C E R E C O R D S...

Page 75: ...E A T T A C H M E N T Version 11 12 E...

Page 79: ...INFORMATIONON THE SERVICE LIFE OF L W HIGH PRESSURE HOSES...

Page 87: ...ANNEX...