SERVICE LIFE

Information on the service life of

L&W high pressure hoses

Version: 2020-06-01

Page - 7

Service life of L&W high pressure hoses

When determining the service life or the replacement interval of the individual hose lines, the

concrete specifications and recommendations of the hose line or machine manufacturer

must be observed. Furthermore, empirical values resulting from previous tests done under the

prevailing operating conditions on site are also relevant.

Guideline values for recommended replacement intervals of hose lines which have proven

themselves in practice are summarized below.

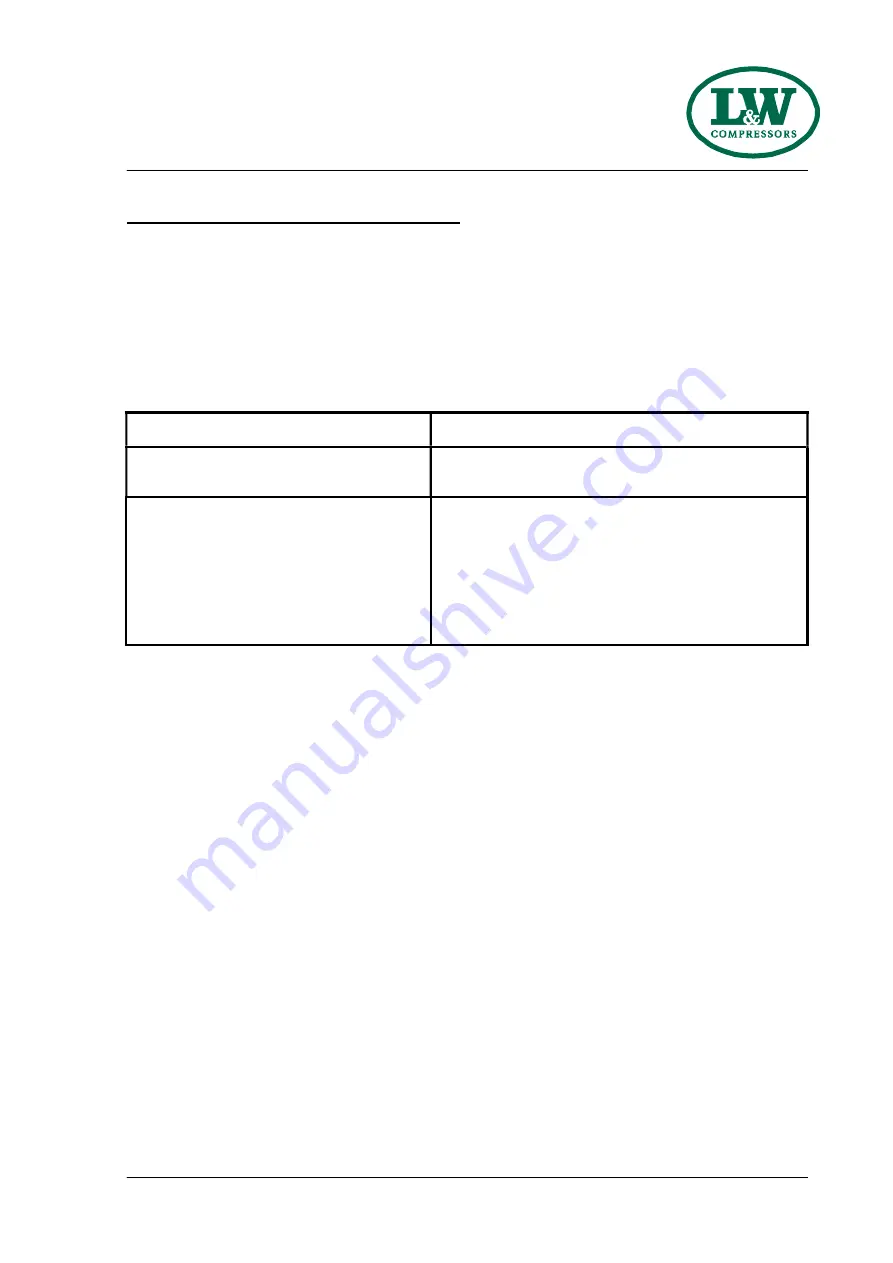

Hose line requirements

Recommended replacement intervals

Standard requirements

6 years

(Service life including a maximum of 2 years storage

time)

Increased requirements, e.g. due to

- increased operating time,

e.g. multi-shift operation, or short machine

or pressure pulse cycle times

- strong external and internal influences (due

to the medium), which greatly reduce the

service life of the hose line

2 years (service life)

The guideline given above for a replacement interval of six years for hose lines meeting normal

requirements includes a maximum storage period of two years. The guideline value of two years

for hose lines meeting increased requirements represents the maximum permissible service life.

A prolongation of the guideline values given above for replacement intervals is possible if

appropriate test values and empirical values are available from the operator of the

machine which permit safe continued use beyond the recommended maximum service

period,

a hazard or risk assessment, documented in writing, has been carried out by the operator, which

also takes into account protective measures in the event of failure of hose lines, and

tests for safe working conditions are carried out by qualified persons at appropriately

set, if necessary reduced, intervals.

It must be ensured that the prolongation of the replacement intervals does not result in a

dangerous situation that could injure employees or other persons.

If hose lines fail during operation or if damage or defects are frequently detected during the

recurring tests, then, in addition to investigating the causes, the test and replacement intervals must

be shortened.

Summary of Contents for SC-300 E

Page 3: ...A Operating Instructions Breathing Air Compressor LW SC 300 E LW SC 350 E Version 12 22 E...

Page 12: ...A S A F E T Y P R E C A U T I O N S...

Page 19: ...A I N S TA L L AT I O N...

Page 26: ...A O P E R AT I O N...

Page 34: ...A R E M E D Y I N G FA U LT S...

Page 39: ...A M A I N T E N A N C E A N D S E R V I C E...

Page 67: ...A M A I N T E N A N C E R E C O R D S...

Page 75: ...E A T T A C H M E N T Version 11 12 E...

Page 79: ...INFORMATIONON THE SERVICE LIFE OF L W HIGH PRESSURE HOSES...

Page 87: ...ANNEX...