8

4. INSTALLATION

WARNING:

INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL

QUALIFIED TO WORK WITH ELECTRICITY AND PLUMBING.

IMPROPER INSTALLATION CAN CAUSE INJURY TO PERSONNEL

AND/OR DAMAGE TO EQUIPMENT. UNIT MUST BE INSTALLED IN

ACCORDANCE WITH ALL APPLICABLE CODES.

NOTICE:

The data plate is located on the inside of the hood wrap. The

Clamshell® voltage, wattage, serial number, clearance and gas

specifications are on the data plate. This information should be

carefully read and understood before proceeding with the installation.

NOTICE:

This unit is approved to be installed only on equipment which meets

NSF standards, and for which the adapter kit is provided.

4.1 Electrical Connection

The Clamshell® is supplied with a cord. The receptacle is not provided with the Clamshell®.

Follow the receptacle manufacturer’s instructions when connecting the cord to the power supply.

4.2 Gas Connection

WARNING:

BEFORE LIGHTING, USE A SOAP AND WATER SOLUTION TO TEST

ALL JOINTS FOR GAS LEAKS.

This Clamshell® is manufactured for use with the type of gas indicated on the nameplate. Contact the

factory if your type of gas does not match the nameplate data.

All gas connectors must be in accordance with local codes and comply with the National Fuel

Federal Gas Codes ANSI Z223.1 latest edition.

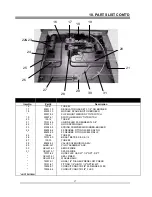

There are two gas connections involved in the installation of the Clamshell®:

The first is the gas supply to the Clamshell® itself. This connection should be made positioning

the manual shut-off valve supplied with the Clamshell® to isolate the appliance from the kitchens

main gas supply during any future service activity (See figure 1). (A service agent should be able

to shutoff and disconnect the gas supply to the Clamshell® without effecting the main gas supply

to the kitchen.) Use gas lines that have a minimum diameter of at least 1/2 an inch.

The second is the gas supply to the base appliance (the appliance to which the Clamshell® is

mounted). The Clamshell® has an external solenoid valve (the Automatic Cutoff Valve (ACV))

at the end of a flexible conduit. The ACV must be installed in line with the gas supply to the base

appliance in a location, which will ensure the ACV is not exposed to temperatures above 175

°

F

(See figure 1). Remove the cover to the ACV to ensure the correct flow direction through the

valve when making the connections. Replace the cover after the connections are complete. Use

gas lines that have a minimum diameter of at least 1/2 an inch.

NOTE: If this Clamshell® is received already mounted on a Lang griddle no further installation is

required. If this Clamshell® is a separate unit proceed to section 4.3 below.

NOTICE:

The installation of any components such as a vent hood, grease

extractors, fire extinguisher systems, must conform to their applicable

National, State and locally recognized installation standards.

4.3 Installation Instructions

Refer to the Installation instructions provided with the adapter kit, on how to connect this Clamshell®

to the griddle/charbroiler.

Summary of Contents for AGC

Page 18: ...18 11 WIRING DIAGRAM...