1

INSTALLATION

RECEIVING THE OVEN

Upon receipt of the appliance, check for freight

damage both visible and concealed. Visible

damage should be noted on the freight bill at the

time of delivery and signed by the carrier's

agent. Concealed loss or damage means loss or

damage which does not become apparent until

the merchandise has been unpacked. If

concealed loss or damage is discovered, make a

written request for inspection by the carrier's

agent within 15 days of delivery. All packing

material should be kept for inspection.

Do not

return damaged merchandise to Lang

Manufacturing Company.

File your claim

with the carrier.

Uncrate the appliance as near its intended

location as practical. The crating will help

protect the unit from the physical damage

normally associated with moving it through

hallways and doorways.

DATA PLATE INFORMATION

A data plate is located inside the control

compartment above the control. Look through

the perforated opening above the control panel

and to the left to view the data plate. A

flashlight may be helpful.

The oven voltage, wattage, serial number, wire

size and clearance specifications are on the data

plate.

This information should be carefully read and

understood before proceeding with the

installation.

VENTILATION AND

CLEARANCES

Standard minimum clearance from

combustible

construction is as follows:

2 inches from sides

4 inches from back

6 inches from floor

These ovens may be set directly, without legs, on

a curbed base or

non combustible

floor.

If the oven is set without legs on a

non

combustible

floor or a curbed base, maintain a 4

inch back clearance.

If the oven is set directly against a

non

combustible

back wall, maintain a 6 inch

clearance to the floor.

Do not

install the oven closer than 3 inches from

another oven on the right hand side (control

panel side).

Do not

install the oven closer than 12 inches

from an uncontrolled heat source (char broiler

etc.) on the right side.

Keep the appliance area free and clear of

combustible material and do not obstruct the

flow of combustion or ventilation air.

The installation of any components such as a

vent hood, grease extractors, and/or fire

extinguisher systems, must conform to the their

applicable nationally recognized installation

standards.

LEGS

Legs are available for both the single and double

deck installations. Single deck installations

require a 27 inch leg. Double deck installations

require a 6 inch leg or caster.

To install the 27 inch legs, place cardboard on

the floor and gently tip the oven onto its back.

Fasten two legs to the oven's front corners using

the four 5/16 diameter bolts provided in the leg

kit. Lift the oven onto the front legs and block

the back of the oven using one of the 27 inch

legs set upside down in the center rear of the

oven body. Install the last 27 inch leg onto the

oven body on the control side rear. Gently lift

the oven rear and remove the leg set to support

the oven center and install it on the last rear

corner.

To install the 6 inch legs or casters, attach the

leg/caster to the supports supplied with the oven

(located inside the oven cavity in a box labeled

Leg Pads). Follow the instructions in the Leg

Pad box to attach the pad to the oven.

The adjustable feet on the bottom of each leg

may be screwed in or out as necessary to level

the oven.

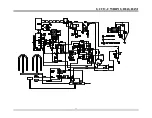

Summary of Contents for GCCO-C

Page 16: ...13 GCCO C WIRING DIAGRAM...