7

wire attaches to the throttle servo arm

with an e-z connector.

5) Slide the horizontal stabilizer in the slot

at the rear of the fuselage. Using your

ruler or measuring tape, center the

stabilizer in the opening. Attach the

wing to the fuselage and block up the

airplane with the wingtips equal

distance from the table. Measure the

stabilizer at the tips. It should measure

the same from each tip to the table. If

the tips are not equal distance from the

table , use sandpaper to sand down the

stab mounting platform until the proper

alignment is achieved. Now measure

from the tip of the stab to the trailing

edge of the wing and adjust the stab

too, so the tips are equal distance from

the trailing edge. Now mark the

stabilizer where it and the fuselage meet

on both side, top and bottom. Now

remove the covering inside of lines.

(Note: Don’t remove the covering up to

the lines. Stay approximately

1/16”inside the lines.)

See the

illustration in the back of the manual

.

Now glue the stab in place using 30-

minute epoxy, rechecking all your

measurements before the epoxy sets.

Set aside to dry. When the epoxy has

cured, run a bead of medium CA as filler

in the gap between the stab and the

fuselage side. Now add the elevator

halves, using the same method used for

hinging the ailerons to the wings.

6) Now install the hinges in the rudder and

trail fit it to the fin. When you are

satisfied with the fit, remove the rudder

and apply 5-minute epoxy to the hole

and slot for the tailwheel wire. When

the epoxy is dry, install the rudder using

same method used for hinging the other

surfaces. Keep the gap as close as

possible while letting the rudder turn

freely.

7) Now slide the tailwheel bracket on the

tailwheel wire up to the fuselage. Using

the bracket as a guide, drill the mounting

holes through the mount. Secure the

bracket with the screws provided.

Install the tailwheel and collar, making

sure the wheel turns freely.

See the

drawing in the back of the manual.

8) Locate the following hardware: 4 nylon

clevises, 4 brass collets, 4 threaded

couplers, 2 control brackets, 2 control

horns, 1 threaded rod, 2 nuts, 2 washers,

and 2 hardwood blocks. Mark & drill a

1/8” hole through the rudder for the

threaded rod, in line with the exit holes

for the rudder cable. Use the nuts and

washers to secure the threaded rod.

Thread a horn bracket on each side of

the rod. Using a pair of wire cutters, cut

the cable into two equal lengths. Install

a coupler at one end of each cable.

9) Insert the cable through the brass collet,

then into the coupler, and back into the

brass collet. Loop it around and back

through the collet again. Squeeze the

collet with pliers and either solder the

assembly with silver solder or apply a

drop or two of thin CA glue.

10) Thread a clevis halfway onto each

coupler and attach the clevises to the

control horns and drop the other end of

the cable into the fuselage theough t he

cable exit holes.

11) Hold the rudder in it’s neutral position

using masking tape. Center the rudder

servo arm. Glue the two hardwood

blocks to the servo tray using medium

CA, to elevate the rudder servo. This

will prevent the rudder servo from

interfering with the other servo arms.

Attach the other two clevises with

couplers to each end of the rudder servo

arm.

12) Now attach the cables to the couplers in

the same manner described above. The

tension should be equal on each side

and the rudder should move freely.

13) Next comes the elevator pushrod.

Mount the two control horns on the

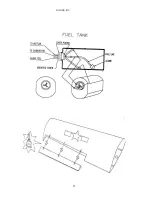

Summary of Contents for Corsair ARF

Page 10: ...10 ...

Page 11: ...LANIER R C 11 ...

Page 12: ...LANIER R C 12 Cowl Mounting Diagram ...

Page 13: ...LANIER R C 13 F4U Corsair Parts Description ...

Page 14: ...LANIER R C 14 Tail Wheel Assembly ...

Page 17: ...LANIER R C 17 Horizontal Stab Wing Alignment ...

Page 18: ...LANIER R C 18 ...

Page 19: ...LANIER R C 19 ...