LANIER

– 1.20 Edge 540T ARF -

INSTRUCTIONS

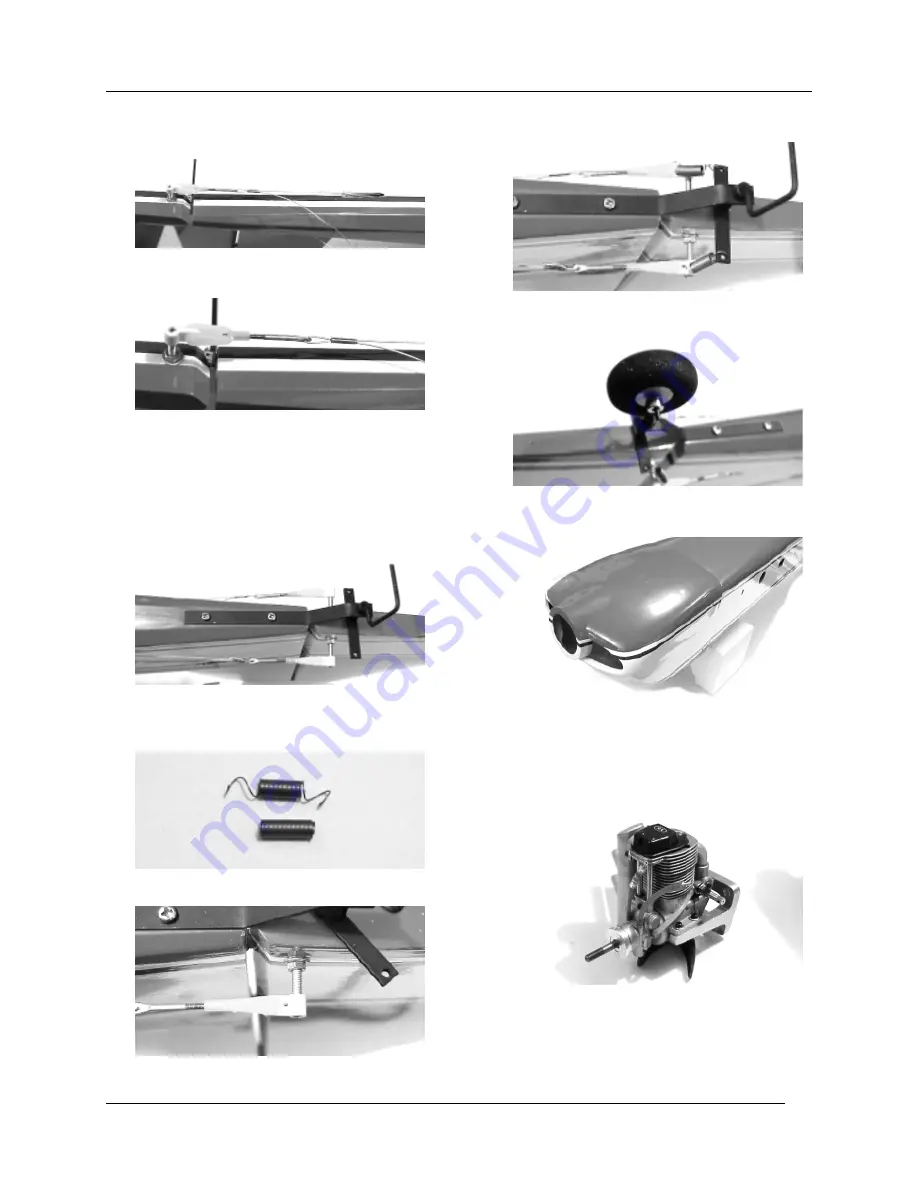

34. Slide the clear tubing over the cables and half

way into the holes in the fuse. Glue in place

with ca.

35. Slide two more cable fasteners down the cable,

then insert the cable through the holes at the end

of the rudder clevis.

Loop the cable back and slide the cable fastener

over the loose end of the cable. Pull the loops as

tight as possible, and then crimp the fasteners.

There should be only slight tension on the cables

to the rudder, and it should be centered. This can

be adjusted by loosening or tightening the clevis

on the cable connectors.

36. Locate the tail wheel bracket and parts.

37. Fasten the tail bracket at the rear of the fuse with

two ½ screws. Drill two 1/16 pilot holes before

installing. Install so the angle is aligned with the

edge of the vertical stabilizer.

.

38. Locate the springs for the tail, and prepare the

ends by bending a loop on each end.

39. Drill a 1/16” hole in the rudder, just past the

clevis.

40. Install a spring on each side of the rudder.

Shorten the springs if needed to put even tension

on the arms and keep the axle centered.

41. Install the tail wheel on the axle, then secure

with the small wheel collar and set screw. Use

some thread lock on the screw.

42. Place the fiberglass cowl on the fuse and fasten

with the ½” #4 screws through the holes.

Measure from the engine crank hole to the

firewall surface with a ruler. Write down the

length. This is the distance that will be from the

firewall to the prop back plate on your motor.

43. Place your engine in your engine mount and bolt

in place with (4) 8-32 x 1” bolts (Dubro #318).

Either tap the holes into the engine mount, or

drill through and lock in place with 8-32 washers

(Dubro #327) and lock nuts (Dubro #329). Try

to position the motor on the motor mount so that

© 2001 Lanier R/C

Page - 6