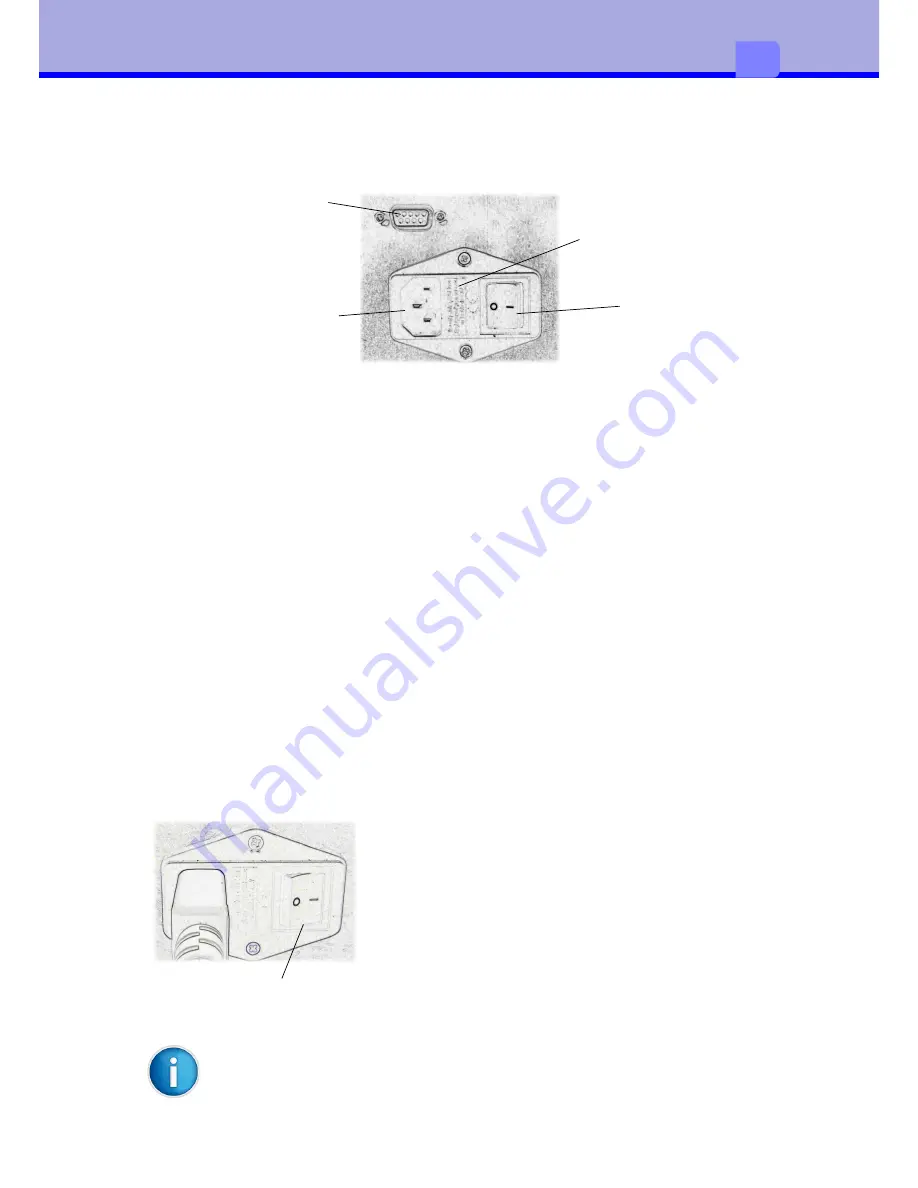

Mains switch

Mains fuse 2A slow blow

Mains connection jack

RS232-Interface

Once all connections have been established it is

possible to switch the laminator on via the mains

switch.

The device carries out initialisation with a

simultaneous self-test. If no error is present, heated

roller heating commences and the display indicates

HEATING

. After roughly 8 minutes the laminator is

ready for operation and the display switches to the

Ready

status

.

11

2

It is assumed that film is already present inside the device.

Mains switch

Connecting the device

Connecting to the power supply

The laminator is equipped with a broad-range power pack for a mains voltage of

100 V to 240 V.

• Ensure that the device is switched off.

• Plug the mains cable into the mains connection jack.

• Plug the mains cable plug into an earthed socket

Connecting to a computer

For configuration and service purposes the laminator must be connected to the

computer with a suitable interface cable (optional).

Switching on the device