11148001

Operating Instructions

Valid from:

23.09.2020

EPIC

®

CRIMPING TOOL DIGITAL

Document: L11148001EN

Page 3 of 10

We reserve all rights according to DIN ISO 16016.

1. General

Your four-indent crimper with a digital display is a hand-crimping tool manufactured using state-of-the-art

technology and recognised safety standards. Only use the crimper if it is in perfect working order. Use the

four-indent crimper for crimping machined pin and socket contacts, and only for the intended purpose stated

in the user manual.

Art. No.

Finish

Profil

Capacity

[mm²]

Capacity

[AWG]

Length

[mm]

Weight

[g]

11148001 Tool with standard indents

in plastic case

(without locator)

0,14 – 6,0

26 - 10

230

1190

11148004 Tool with standard indents

in plastic case

(without locator)

0,08 - 2,5

28 - 13

175

820

This tool allows you to check it at testing intervals you set yourself, and recalibrate as necessary.

The crimper features wear monitoring to increase process reliability for the user. This shows you once the

crimper has exceeded a certain level of wear.

Apart from that, the tool is equipped with a wear prediction feature. This feature shows you when it is time to

recalibrate the crimper depending on how often you have used it and the crimping setting used.

User alteration or improper use of the crimper will invalidate the manufacturer's guarantee for any resulting

damage.

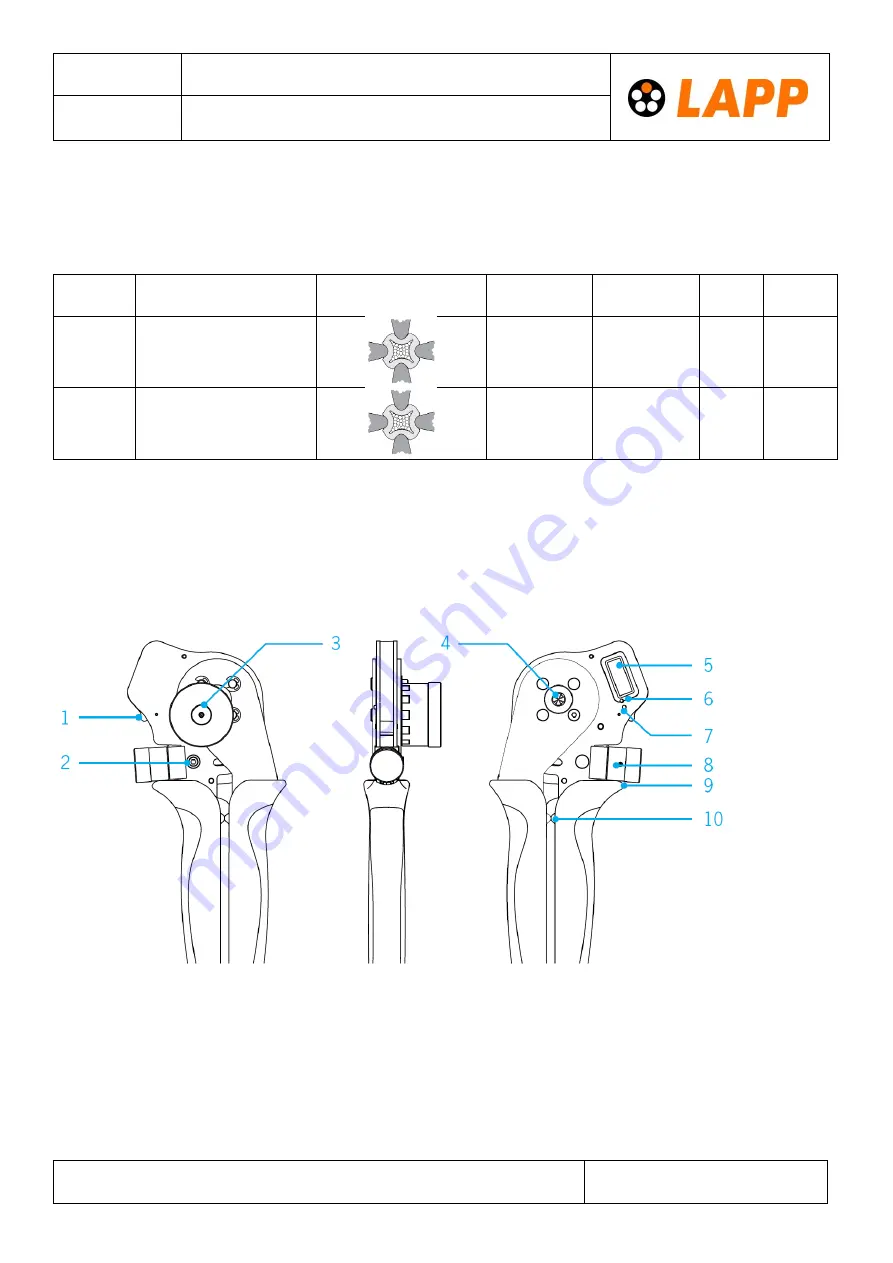

1 Type CR 2025 battery compartment

2 Clamping screw for locking the crimper setting

3 Contact bushing with locking screw (locator)

4 Crimping point

5 Display

6 „MODE“ button(recessed)

7 „ON/OFF“ button

8 Crimp setting adjustment wheel

9 Opening to the emergency open lever

10 Stop