11148001

Operating Instructions

Valid from:

23.09.2020

EPIC

®

CRIMPING TOOL DIGITAL

Document: L11148001EN

Page 7 of 10

We reserve all rights according to DIN ISO 16016.

10. E1 message after calibration or recalibration

If the crimper display shows an E1 message after several calibration or recalibration attempts (the message

will be shown in sequence at irst, then permanently as E1), then the dies in your four-indent crimper are

so worn that the wear can no longer be compensated for. Send your crimper to the manufacturer or an

authorised repair shop for inspections.

11. Monitoring wear – General

Any tool is subject to a certain amount of wear, even if used properly. Press the MODE button (6) for ten

seconds – range: 8 to 15s – for your crimper's current condition with numerical data on the crimper display (5).

The following information will be shown in sequence:

•

Serial number (eight digits in sequence)

•

Remaining lifetime in percent (remaining service life)

•

Reference value – lower setting as specified by the manufacturer

•

Number of calibrations so far

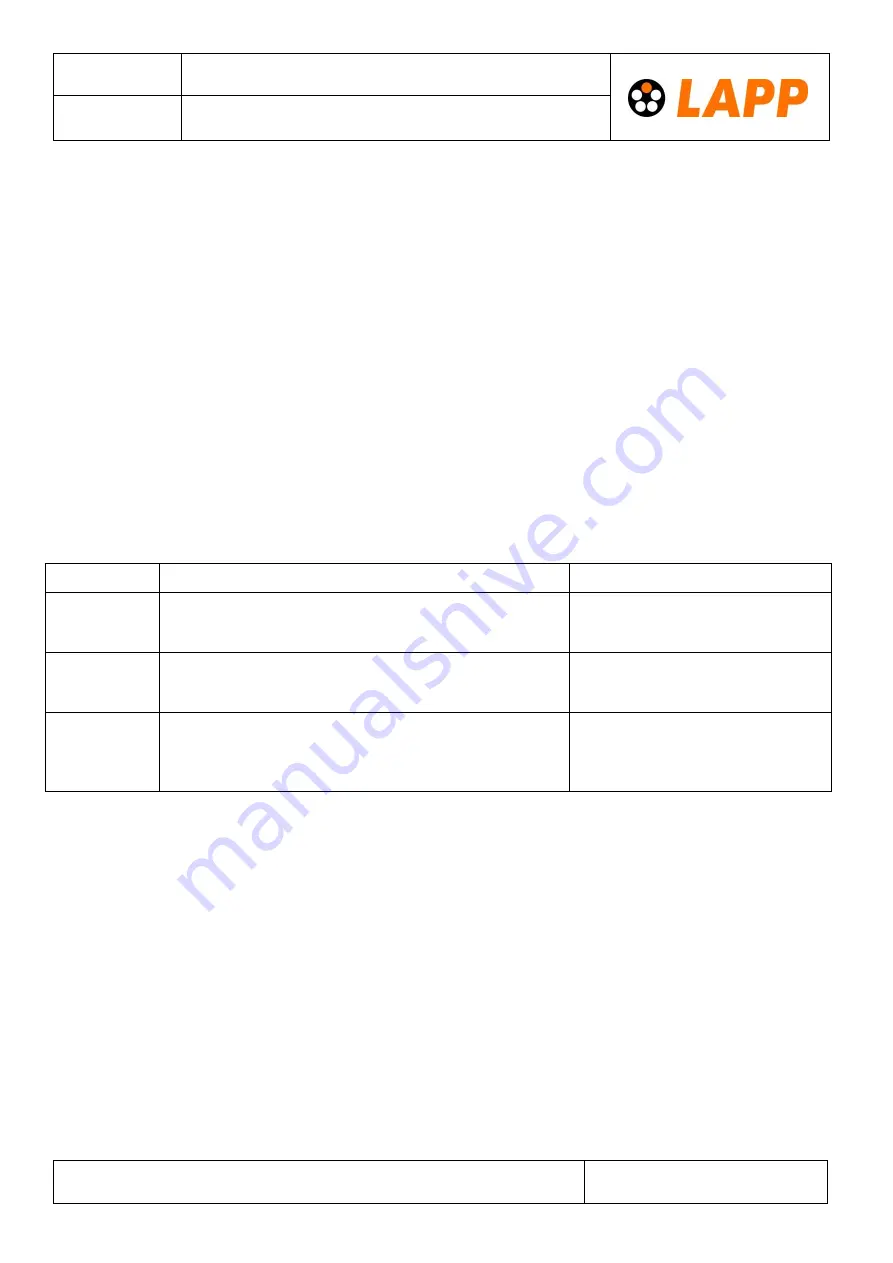

12. Troubleshooting and remedy

Display

Cause

Solution

„E1“

The crimper was not turned down to its lower

(reference) setting using the adjustment wheel

after changing the battery.

Repeat the procedure (See 9,

Calibration after a battery change).

„E1“

The display shows E1 after correct

recalibration–Your crimp dies have reached

their limit of wear.

The crimper dies are worn out. Send

in your

crimper for inspections.

„E2“

Calibration or recalibration at a higher

adjustment value than on initial factory

calibration (too much play between the punch

and gauge).

Repeat calibration or recalibration

with the

gauge supplied (see 8 or 9).

13. Servicing and maintenance

Make sure that your hand crimper is in a clean and proper state before use. Remove any crimping residues from

between the crimping jaws and contact bushing. Lubricate the joints regularly with machine lubricant, and protect

them from soiling. Make sure that all of the pins are secured by retaining rings.

Always have the crimper manufacturer or an authorised repair shop repair your four-indent crimper.