15

EXCALIBUR LINER

English

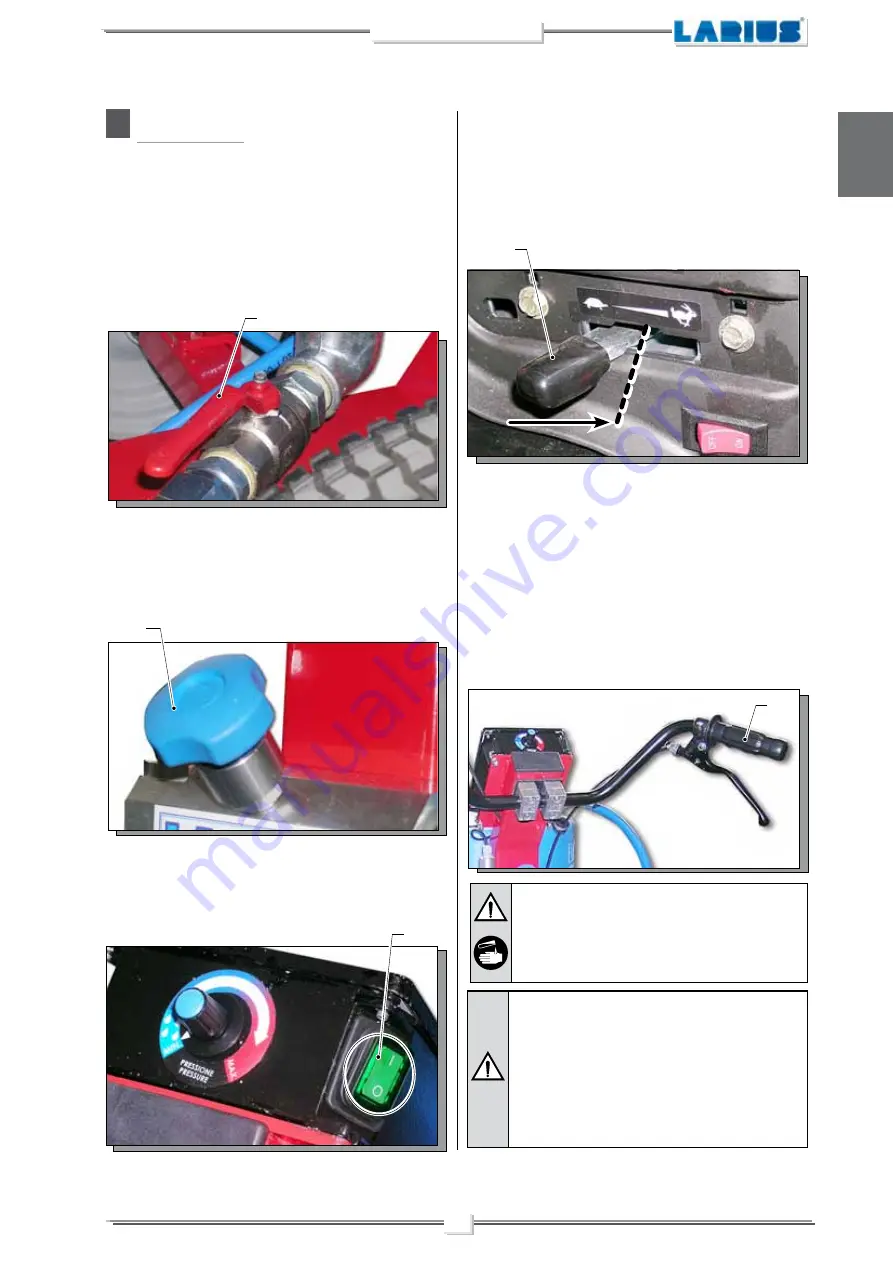

H1

H2

H4

H3

H5

H

WORKING

SETUP PROCEDURE

• Use the tooling after performing all the

SETTING UP

opera-

tions above described.

• Check that there is enough unleaded petrol.

• Open the product output tap (

H1

).

• Start the motor following the indications provided in the

chapter “

STARTING THE MOTOR

”.

• Make sure that the re-circulation/safety valve

(H2

) is closed

(spray enabled)

.

ADJUSTING PUMP UNIT SPEED

• Move the motor acceleration lever (

H4

) gently to increase or

decrease the speed of the pump.

During the painting operation it is normally recommended to

maintain the position of the accelerator lever (

H4

) at about 3/4

of its maximum run.

• Press the switch (

H3

) of the equipment

“ON” (I)

.

•

Turn the pressure adjustment handle clockwise until the

desired setting has been reached.

Recirculating-safety valve: when working at the

maximum pressure available, releasing the gun

trigger sudden increases of pressure can occur.

In this case, the recirculating-safety valve opens

automatically eliminating part of the product from

the recirculating tube.

Then it closes so as to go back to the first working

conditions.

NEVER point the spray gun at yourselves or at

other people. The contact with the casting can

cause serious injuries. In case of injuries caused

by the gun casting, seek immediate medical advice

specifying the type of the product injected.

SPRAY ADJUSTMENT

•

Slowly turn clockwise the pressure control knob to reach the

pressure value in order to ensure a good atomization of the

product.

•

An irregular and marked spray on the sides indicates a low

working pressure. On the contrary, a too high pressure causes

a high fog

(“overspray”)

and waste of product.

• Pull the lever on the right (

H5

) to activate the spray gun and

begin working, advancing the machine in a continuous man-

ner.