17

EXCALIBUR LINER

English

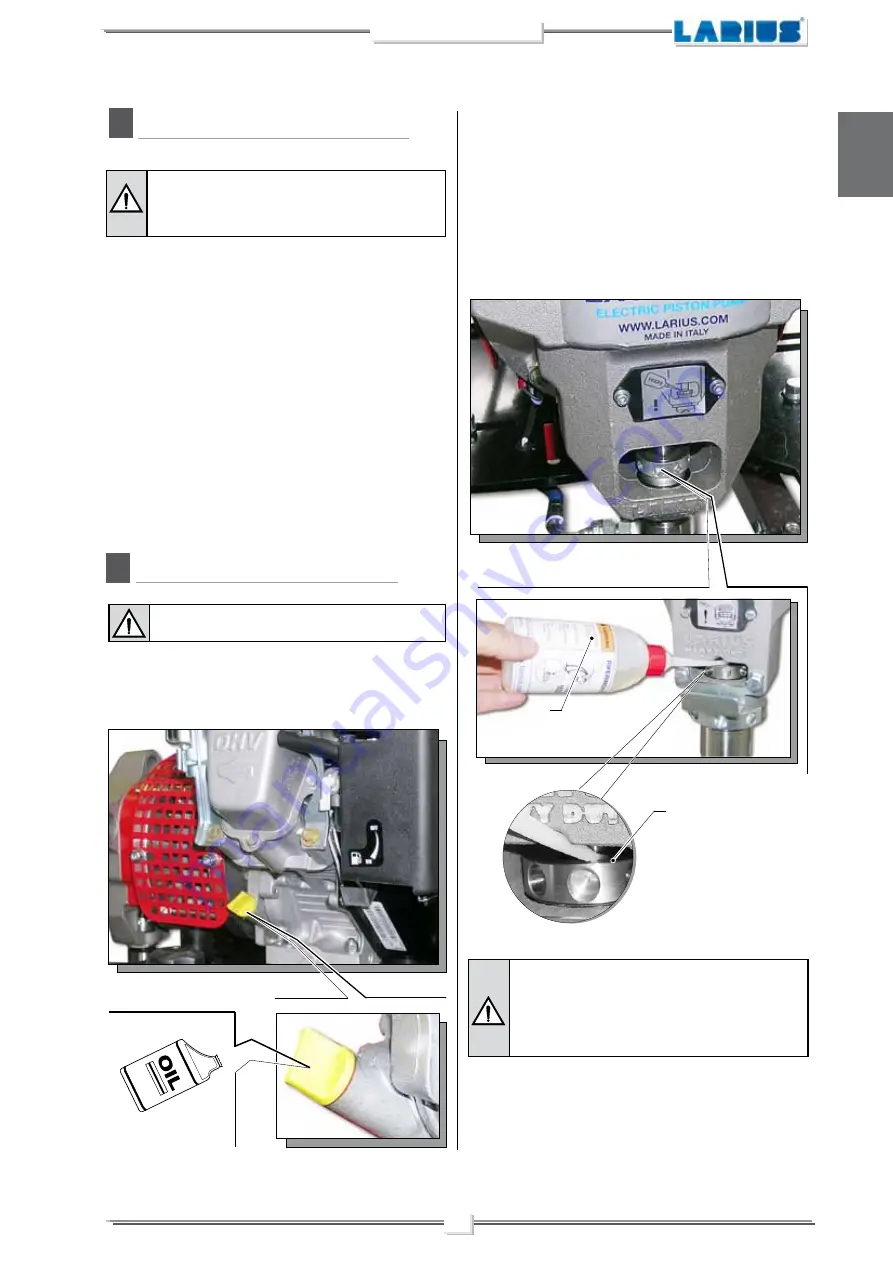

Oil ring

Ref. 16325

K1

GENERAL MAINTENANCE

DAILY

• Clean the filters;

• Clean the nozzles;

• Clean all the varnish circuit with a specific product;

• Check the fuel motor

(see the maintenance table)

.

PERIODICALLY

• Check the pumping gaskets draft

(if the product draws, replace

gaskets)

;

• Clean the mobile parts from the varnish deposits

(spray guns,

etc.)

;

• Check the gun cables tightening, the wheel block;

• Check that the tubes and all the fittings are correctly locked.

J

CHECK ON THE PACKING NUT

Discharge the pressure in the pump unit (open

the discharge valve) before carrying out any

maintenance.

Daily check the packing nut is tight in order to avoid wastes but

not excessively to prevent the piston from seizing and the

gaskets from wearing

.

•

Use the lubricant (

K1

) supplied

(ref. 16325)

to allow an easy

sliding of the piston inside the gasket group.

Daily top up the packing nut.

At the start of each working day check that the

ring nut is full of hydraulic oil (Ref. 16325). This oil

makes it easier for the piston to slide and prevents

any material that escapes via the seal gasket drying

when the equipment is stopped.

ROUTINE MAINTENANCE

Always check that there is oil in the motor.

K

Check the motor oil every 100 working hours via the relevant

measuring caps positioned on the bottom of the petrol motor.

Top up if necessary.