Ediz. 010 - 06/2015

TROUBLESHOOTING

N

Always disconnect the equipment and discharge the pressure before performing any check or replacement of

pump parts

(see "correct procedure of decompression")

.

•

The equipment does not start

•

The equipment does not suck the

product

•

The equipment sucks but does not

reach the pressure desired

•

When pressing the trigger, the

pressure lowers considerably

•

The pressure is normal but the

product is not atomized

•

The atomization is imperfect

•

When releasing the trigger of the

gun, the equipment does not stop

(

the motor runs slowly and the

piston rod moves up and down

)

• Lack of voltage;

• Considerable drops in mains voltage;

• On/Off switch disconnected;

• Breakdown of pressure transmitter;

• Breakdown of motor electric control box;

• The line of material coming out of the

pump is already under pressure;

• The product is solidified inside the

pump;

• Suction filter clogged;

• Suction ilter too fine;

• The equipment sucks air;

• Ball is blocked;

• Lack of product;

• The equipment sucks air;

• The recirculating-safety valve is open;

• The gaskets of the pumping group

are worn;

• Suction or delivery valve dirty;

• Nozzle too big or worn;

• The product is too dense;

• The filter of the gun-butt is too fine;

• The nozzle is partially clogged;

• The product is too dense;

• The filter of the gun-butt is too fine;

• The nozzle is worn;

• The gaskets of the pumping group

are worn;

• Suction or delivery valve dirty;

• Recirculating-safety valve defective;

• Check the correct connection to

the power supply;

• Check the extension cable;

• Ensure the On/Off switch is on the

“on” position and turn clockwise

the pressure control knob;

• Verify and replace it, if necessary;

• Verify and replace it, if necessary;

• Open the drain valve to release

pressure in the circuit;

• Open the drain valve to release

pressure in the circuit and stop

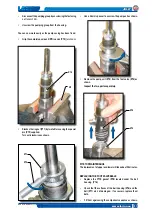

the machine. Disassemble the

pumping group and the pressure

transmitter and clean;

• Clean or replace it;

• Replace it with a larger-mesh filter

(

with very dense products, remove

the filter

);

• Check the suction pipe;

• Press the manual unlocking device;

• Add the product;

• Check the suction pipe;

• Close the recirculating-safety val-

ve;

• Replace the gaskets;

• Disassemble the pumping group;

• Replace it with a smaller one;

• Dilute the product, if possible;

• Replace it with a larger-mesh filter;

• Clean or replace it;

• Dilute the product, if possible;

• Replace it with a larger-mesh filter;

• Replace it;

• Replace the gaskets;

• Disassemble the pumping group

and clean;

• Verify and replace it, if necessary;

Solution

Cause

Problem

Solution

Cause

Problem

www.larius.eu

JOLLY

18