10

English

L

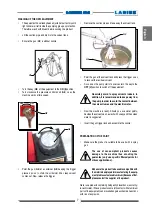

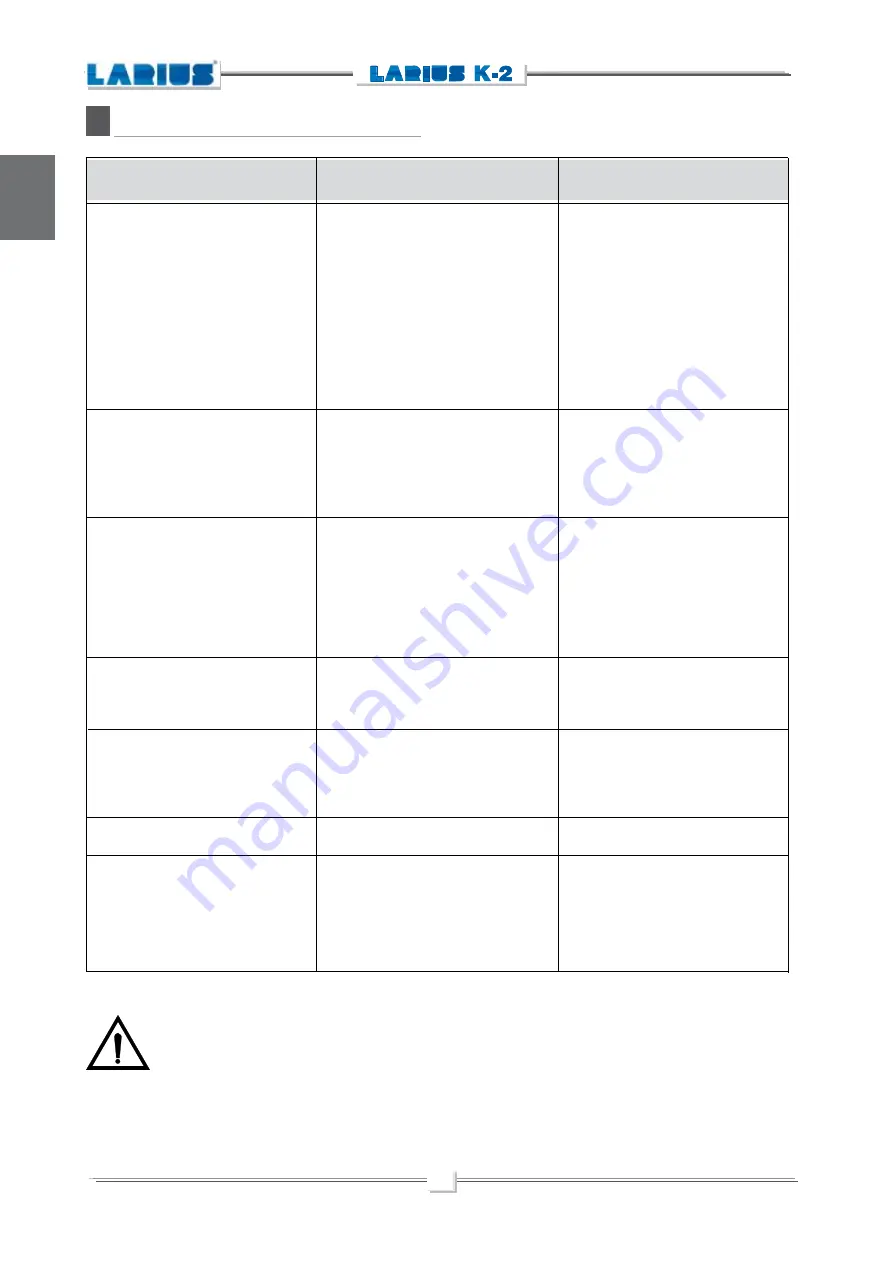

PRoBLEMS AND SoLUTIoNS

Solution

Cause

Problem

•

The equipment does not start

•

The equipment does not suck the

product

•

The equipment sucks but does not

reach the pressure desired

•

When pressing the trigger, the

pressure lowers considerably

•

The pressure is normal but the

product is not atomized

•

The atomization is imperfect

•

When releasing the trigger of the

gun, the equipment does not stop

(

the motor runs slowly and the

piston rod keeps on going up and

down

)

• Lack of voltage;

•

Breakdown of pressure transmitter;

•

Breakdown of motor electric control box;

•

The product is solidified inside the

pump;

•

Suction filter clogged;

•

Suction ilter too fine;

•

The equipment sucks air;

•

Lack of product;

•

The equipment sucks air;

•

The drain valve is open;

•

The gaskets of the pumping group are

worn;

•

Suction or delivery valve dirty;

•

Nozzle too big or worn;

•

The product is too dense;

•

The filter of the gun-butt is too fine;

•

The nozzle is partially clogged;

•

The product is too dense;

•

The filter of the gun-butt is too fine;

•

The nozzle is worn;

•

The gaskets of the pumping group are

worn;

•

Suction or delivery valve dirty;

•

Drain valve defective;

• Check the correct connection to the

power supply;

•

Verify and replace it, if necessary;

•

Verify and replace it, if necessary;

•

Open the drain valve to release

pressure in the circuit and stop the

machine. Disassemble the pumping

group and the pressure transmitter

and clean;

•

Clean or replace it;

•

Replace it with a larger-mesh filter

(

with very dense products, remove

the filter

);

•

Check the suction pipe;

•

Add the product;

•

Check the suction pipe;

•

Close the drain valve;

•

Replace the gaskets;

•

Disassemble the pumping group;

•

Replace it with a smaller one;

•

Dilute the product, if possible;

•

Replace it with a larger-mesh filter;

•

Clean or replace it;

•

Dilute the product, if possible;

•

Replace it with a larger-mesh filter;

•

Replace it;

•

Replace the gaskets;

•

Disassemble the pumping group and

clean;

•

Verify and replace it, if necessary;

Always close the air compressed supply and unload the plant pressure before performing any check or repla-

cement of pump parts (

see "correct procedure of decompression"

).