13

English

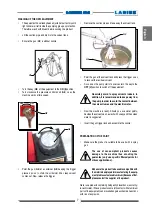

P1

P3

P2

oN

oFF

P

CLEANING AND/oR RE-

PLACEMENT oF THE PRES-

SURE TRANSMITTER

CHECK oN THE PRESSURE TRANSMITTER

Before evaluating if the cause of the malfunction is due to the pres-

sure transmitter or to the electric control box, proceed as follow:

• Check the correct connection to the power supply.

• Make sure that the key

(

P1

) is on the

oN

(I)

position.

• Turn a little the pressure control knob (

P2

) clockwise till the

electric motor starts.

• In case, after these checks, the tooling does not start, verify

the pressure transmitter.

• Make sure the equipment does not suck materials

(remove

the product tank)

.

• Open the drain valve (

P3

).

• Disassemble the pumping group as shown on the previous

chapter.

Pressure

sensor

Pressure pin

• Remove the pressure sensor from its housing and chek if

the pin can move. If necessary, clean thoroughly.

• Check the seals (O-ring and teflon ring): if worn or "pinched",

replace them.

• Disassemble the supporting block and check the microswitch

operates properly by using a tester. If damaged, replace it.

• Reassemble the whole unit centering the block with the

fastening screws.

• Reassemble the whole unit and start again the machine

following the procedure indicating.

• If the machine

does not start

, check the electrical connections

and the motor electric control box: if damaged, replace it.