6

English

High pressure hose

G

•

TIGHTEN AND CHECK ALL THE FITTINGS FOR CONNEC-

TION BETWEEN PUMP, FLEXIBLE HOSE AND SPRAY GUN

BEFORE USING THE EQUIPMENT.

•

ALWAYS USE THE FLEXIBLE HOSE SUPPLIED WITH

STANDARD KIT. THE USE OF ANY ACCESSORIES OR

TOOLING OTHER THAN THOSE RECOMMENDED IN

THIS MANUAL, MAY CAUSE DAMAGE OR INJURE THE

OPERATOR.

•

THE FLUID CONTAINED IN THE FLEXIBLE HOSE CAN

BE VERY DANGEROUS. HANDLE THE FLEXIBLE HOSE

CAREFULLY. DO NOT PULL THE FLEXIBLE HOSE TO

MOVE THE EQUIPMENT. NEVER USE A DAMAGED OR

A REPAIRED FLEXIBLE HOSE.

The high speed of travel of the product in the

hose can create static electricity through di-

scharges and sparks. It is suggested to earth

the equipment.

The pump is earthed through the earth cable of the supply.

The gun is earthed through the high pressure flexible hose.

All the conductors near the work area must be earthed.

•

NEVER SPRAY OVER FLAMMABLE PRODUCTS OR SOL-

VENTS IN CLOSED PLACES.

•

NEVER USE THE TOOLING IN PRESENCE OF POTEN-

TIALLY EXPLOSIVE GAS.

Always check the product is compatible with

the materials composing the equipment

(pump,

spray gun, flexible hose and accessories)

with

which it can come into contact. Never use

paints or solvents containing halogen hydrocarbons

(as the

methylene chloride)

.

If these products come into contact with aluminium parts can

provoke dangerous chemical reactions with risk of corrosion

and explosion.

IF THE PRODUCT TO BE USED IS TOXIC, AVOID INHALATION

AND CONTACT BY USING PROTECTION GLOVES, GOGGLES

AND PROPER FACE SHIELDS

TAKE PROPER SAFETY MEASURES FOR THE PROTECTION

OF HEARING IN CASE OF WORK NEAR THE PLANT.

Electrical safety precautions

•

Check the "ON/OFF" switch is on the "OFF" position before

connecting the cable to the mains.

•

Never carry a plugged-in equipment.

•

Disconnect the equipment before storing it and before per-

forming any maintenance operation or replacing of acces-

sories.

•

Do not carry the equipment neither unplug it by pulling the

electric cable.

Protect the cable from heat, oil and sharp edges.

•

When the tool is used outdoors, use only an extension cable

suited for outdoor use and so marked.

Never attempt to tamper with the calibre of

instruments.

• Take care when the pumping rod is moving.

Stop the machine whenever someone is within its vicinity.

•

Repairs of the electrical equipment should only be carried

out by skilled personnel, otherwise considerabledanger to

the user may result.

SETTING-UP

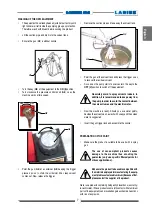

CoNNECTIoN oF THE FLExIBLE HoSE To THE GUN

• Connect the high pressure flexible hoses to the pump and the

guns tightening the fittings strongly

(the use of two wrenches

is suggested)

.

NEVER

use sealants on fittings threads.

It is

ADVISED

to mount a high pressure manometer at the

pump outlet

(see on page "Accessories")

to read the product

pressure.

• It is recommended to use the hose provided with the standard

kit.

NEVER

use a damaged or a repaired flexible hose.