Ed. 003 - 02/2013

Do not plug in or unplug any power supply cords

in the dispensing area when there is any chance

of igniting fumes still in the air.

If you experience any static sparking or feel even

a slight shock while using this equipment, STOP

DISPENSING IMMEDIATELY. Check for proper groun-

ding of the entire system. Do not use the system

again until the cause of the problem is identified

and corrected.

Before flushing, be sure the entire system and

flushing pails are properly grounded. Refer to

GROUNDING, above. Always use the lowest possi-

ble fluid pressure, and maintain firm metal-to-metal

contact between the gun and grounded metal pail

during flushing to reduce the risk of fluid injection

injury, static sparking and splashing.

MOVING PARTS HAZARD

Moving parts can pinch or amputate your fingers or other body

parts. Keep clear of moving parts when starting or operating your

system.

Before checking or servicing the gun, pump, or any other system

component follow the

PRESSURE DISCHARGING PROCEDURE

to prevent the pump from starting accidentally.

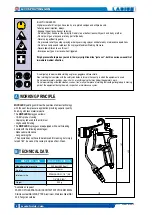

GROUNDING

To reduce the risk of static sparking, ground the pump and all

other equipment used or located in the dispensing area. Check

your local electrical code for detailed grounding instructions for

your area and type of equipment and be sure to ground all of the

following equipment.

• Pump: ground the pump by connecting a grounding wire from

the pump’s grounding lug to a true earth ground.

• Air compressor or hydraulic power supply: ground according

to local code and manufacturer’s recommendations.

• Fluid hoses: use only grounded hoses with a maximum of

150 mt. Combined hose length to ensure grounding continuity.

Refer to hose grounding continuity, above.

• Flo-gun: obtain grounding through connection a properly

grounded fluid hose and pump.

• Fluid supply container: according to local code.

• All solvent pails used when flushing: according to local code.

Use only metal pails. do not place the pail on a non-conductive

surface, such as paper or cardboard, which interrupts the

grounding continuity.

• To maintain grounding continuity when flushing or relieving

pressure always hold a metal part of the gun firmly to the side

of a grounded metal pail, then trigger the gun.

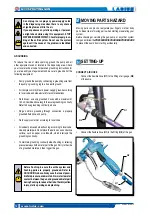

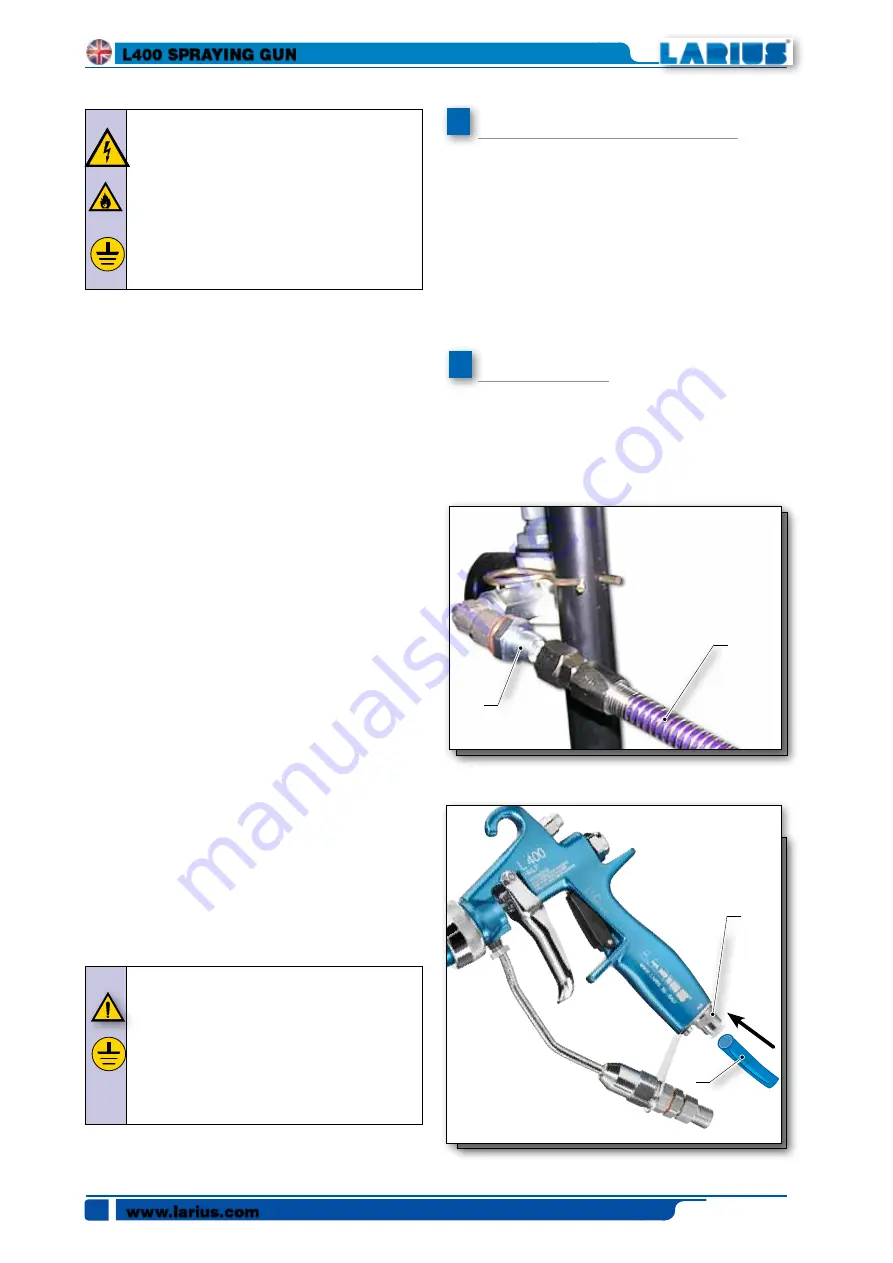

SETTING-UP

CONNECT AIR HOSE

•

Connect the flexible hose (

N1

) to the fitting of air gauge (

N2

)

of the pump.

•

Connect the flexible hose (

N1

) to the fitting (

N3

) of the gun.

M

N

www.larius.com

L400 SPRAYING GUN

14

N1

N2

N1

N3