Ed. 003 - 02/2013

At this point the procedure for the coupling group replacement

is completed.

Reassemble the gun following the previous procedure in reverse

order.

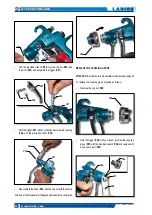

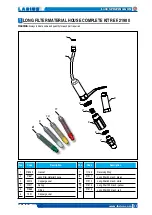

REPLACE THE AIR VALVE GASKET

ATTENTION

:

for further details, please refer to the drawing on page 22

To replace the air valve gasket, porceed as follows:

• Use the provided wrench (

P41

) to remove the rear cap (

P42

)

and the spring (

P43

) and (

P44

) .

During this operation, make sure that the needle is

not damaged or worn (P40). If necessry, replace it

as described in the previous paragraph “Replace

product gasket”.

• Use the provided wrench (

P48

) to unscrew the nut (

P46

) and

the pivot (

P47

) and disassemble the trigger (

P45

).

• Remove the air valve (

P49

) by using poined pointed pliers

(

P50

) .

• Remove the ring nut (

P51

) and the coupling (

P52

).

www.larius.com

L400 SPRAYING GUN

21

P40

P39

P42

P41

P43

P44

P42

P45

P46

P47

P48

P45

P49

P50

P51

P52