15

MIST-LESS GUN

English

ROUTINE MAINTENANCE

R

To reduce the risk of serious injury, including fluid

injection or splashing the eyes or on the skin:

• Always follow the PRESSURE RELIEF PROCE-

DURE (

see page 8

) before checking, adjusting,

cleaning or repairing the gun or any part of the

system.

• After adjusting or servicing the gun, if fluid does

flow, the gun is not assembled properly or the

trigger lock is damaged, reassembled the gun

or return it to your nearest distributor. Do not

use the gun until the problem is corrected.

• When removing the gun from the hose, be sure to

hold the inlet fitting securely to avoid loosening

from the gun body.

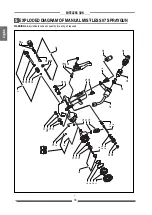

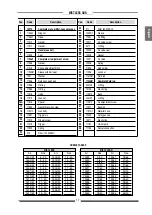

INSPECTING THE VALVE FOR OBSTRUCTIONS OR DAMGE

PLEASE NOTE:

for details see the exploded diagram on page 16.

If fluid continues to flow after the trigger is released, the gun valve

may be obstructed or need adjustment. The valve stem (

34

) or

valve seat (

10

) may be worn or damaged. Adjust or replace parts

as instructed below. To reduce the risk of serious injury, do not

use the gun until the problem is corrected.

• Follow the Pressure Relief Procedure (

see page 8

) and

disconnect the gun from the hose.

• Disassemble the gun as instructed, then clean and inspect

the parts.

• Replace any worn or damaged parts and reassemble the

gun as instructed.

VALVE NEEDLE AND SEAL SERVICE

PLEASE NOTE:

for details see the exploded diagram on page 16

If fluid flows beyond the seal, the gaskets (

8

) or the rod (

34

) might

be damaged or worn.

To replace them, follow the procedure described below:

• Be sure to read the WARNING (

see page 6

).

• Follow the Pressure Relief Procedure (

see page 8

) and

disconnect the gun from the hose.

•

Loosen the spring adjustment fitting (9) and remove the spring

(

22

).

•

Unscrew the sleeve (

10

), clean or replace it if necessary.

• Remove the needle (

34

),clean it and, if necessary, replace

it.

• Remove the gasket pressing screw (

17

) and the gasket (

16a

).

Replace the gaskets.

• Fit the gasket pressing screw.

• Insert the needle (

34

).

• Screw the coupling sleeve (

10

) with the dedicated washer

(

11

) into the gun body (

18

).

The needle (34) and the coupling sleeve (10) must

be accurately fitted: during the last turn of the

screwing coupling sleeve (10) must compress the

needle (34) to provide the proper seal.

If thematerial will leak from the valne while ope-

rating the gun:

• proceed with the pressure release as discribed

at page 8

• Disassemble the coupling sleeve(10) and turn

the needle (34) anticlockwise. In this way the

spring (22) compression will be increased and

seal will be more accurate.