Ediz. 02 - 07/2016

www.larius.eu

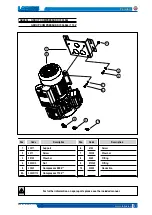

PEGASO

20

T

The air hose fitting on sprayer can get hot! Allow sprayer to cool down 5 minutes before removing

air hose.

MAINTENANCE PROGRAMME

After ever use

Daily

•

Flexible air and material hoses

•

Air and material hose

connections

•

Gun

•

Nozzle gun

•

Pump

•

Compressor

•

Support pressure

•

Flexible product hose

• Checking for wear or breaks

• Clean and wash internal parts

• Wash accurately

• Wash the internal hose

• No maintenance required

• Drain the water

• We suggest adding a few drops

of light mineral oil

• Inspect for signs of wear

• Add drops of light oil underne-

ath the trigger

• We suggest adding a few drops

of light mineral oil

• Check the product passage

hose to see if it is worn or da-

maged (to replace it, see next

page).

• Clean

• Clean the sensor pawl of any

encrustations. Replace if worn

or broken (to clean or replace

see page 22).

• Suggested after use and when

changing material, make the

sponge sphere pass through the

hose (see procedure on page 17).

• To keep sprayer in good operating condition, always clean it thoroughly and prepare it properly for storage.

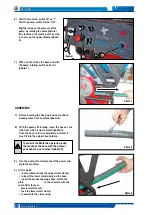

ROUTINE MAINTENANCE

• Before removing the flexible material passage hose, release the pressure.