Summary of Contents for Pegaso

Page 1: ...ENGLISH MAINTENANCE INSTRUCTION MAINTENANCE INSTRUCTION OPERATING AND OPERATING AND ...

Page 2: ......

Page 5: ...3 PEGASO English A 890 500 Ø 300 C 1050 D 900 55 B 730 ...

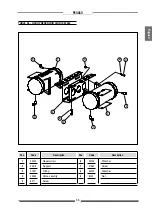

Page 6: ...4 PEGASO English 14 3 1 5 4 6 7 12 8 13 9 10 11 2 15 16 17 18 ...

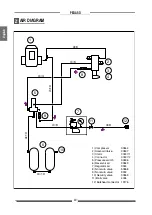

Page 44: ...42 PEGASO English ...

Page 45: ......