Ed. 004 - 06/2013

www.larius.com

STAR 3001S GUN

24

L1

L2

L2

L1

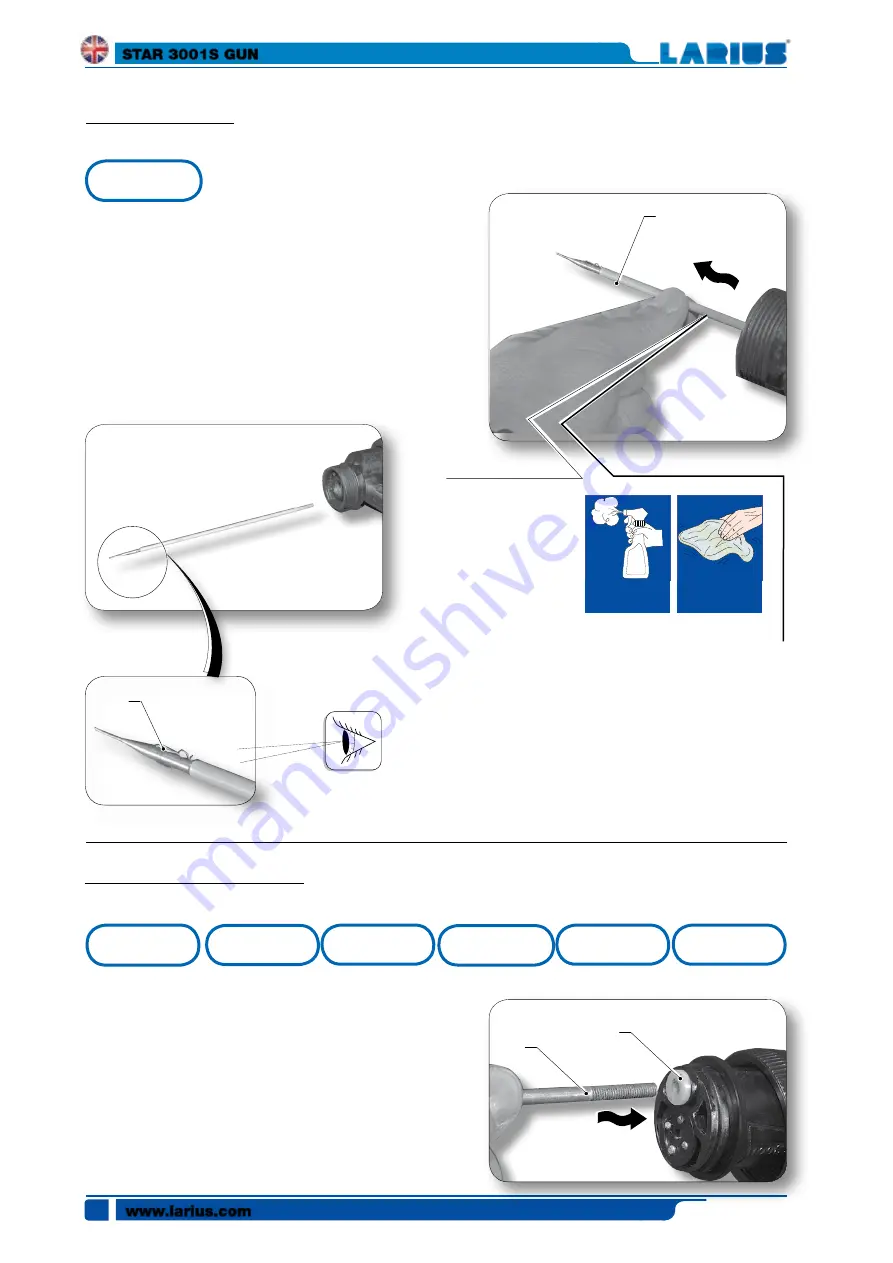

• Extract the needle (

L1

), making sure to remove it from the

front towards the rear side in order to avoid the damaging of

the delicate components.The needle is composed of a main

body made of a special non-conductive material. The front

side houses the metal tip (

L2

).

• Check the wear of the tip (

L2

) and replace it, if necessary.

• Check that the body of the needle is not damaged or worn.

Replace it, if necessary.

• Duly clean this component.

L.d.1 - Remove the needle

This procedure shall be carried out for guns with:

L.e - REMOVE THE NEEDLE SUPPORT

• Insert a M5 screw (

L1

) inside the needle support (

L2

) and use

it to remove the needle support (

L2

).

CLEANER

Liquid Cleaner

Clean

LOW PRESSURE

FAN TIP

This procedure shall be carried out for guns with:

LOW PRESSURE

CONE TIP

AIRLESS

FAN TIP

MISTLESS

FAN TIP

MISTLESS

CONE TIP

LOW PRESSURE

FAN TIP

AIRLESS

CONE TIP