17

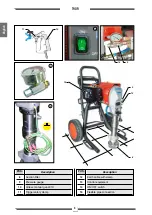

THOR

English

•

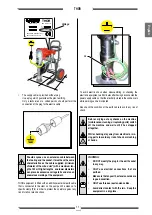

. Reduce.pressure.to.the.minimum.

(turn counterclockwise the

pressure control knob

(

H1

)

)

.

•

Press.the.switch.(

H2

).placed.on.the.box.of.the.electric.motor,.

to.stop.the.equipment.

•.

Hold.the.spray.gun.trigger.down.

•.

Open.the.circulation.tap.(

H3

).to.discharge.the.pressure.in.

the.circuit.

•.

Lift.the.suction.hose.and.replace.the.bucket.containing.the.

product. with. a. bucket. of. cleaning. liquid.

(make sure it is

compatible with the product you are using)

.

•.

Unscrew.the.nozzle.on.the.spray.gun.

(remember to clean it

with cleaning liquid)

.

•

Press.the.switch.(

H2

).“

ON”

(I)

.of.the.equipment.

H1

H2

OFF

ON

H2

Open

H3

Summary of Contents for THOR

Page 53: ...THOR FIELDS OF APPLICATION ...