ZEUS

8

English

D

ALARM MESSAGE TABLE

Cause

Type of alarm

Alarm symbol

F1

F2

F3

F4

F5

F6

F7

F8

Maximum current

Dissipator temp.

Motor temp.

Maximum voltage

Minimum voltage

Earth connection

Pressure sensor missing

Automatic switch-off during circulation

phase (15 minutes)

The motor’s current absorption is too high

The dissipator temperature is too high

The motor temperature is too high

The voltage is too high

The voltage is too low

The earth connection is disconnected

or non-existent

The pressure sensor is damaged or

not fitted

The equipment is in cleaning mode

Check the mechanical and hydraulic

condition of the equipment. If necessary,

take action

Check that the dissipator surfaces are

clean and that the dissipator is properly

ventilated

Check that the motor’s heat dissipation

surfaces are clean. Check that cooling

ventilation is correct

Check the connection to the electrical line

and reinstate the correct nominal voltage

Check the connection to the electrical line

and reinstate the correct nominal voltage

Check the earth cable and, if necessary,

replace it. Make sure that the machine

is earthed

Replace it

Wait until the equipment has stopped

completely before using it for a new job

Solution

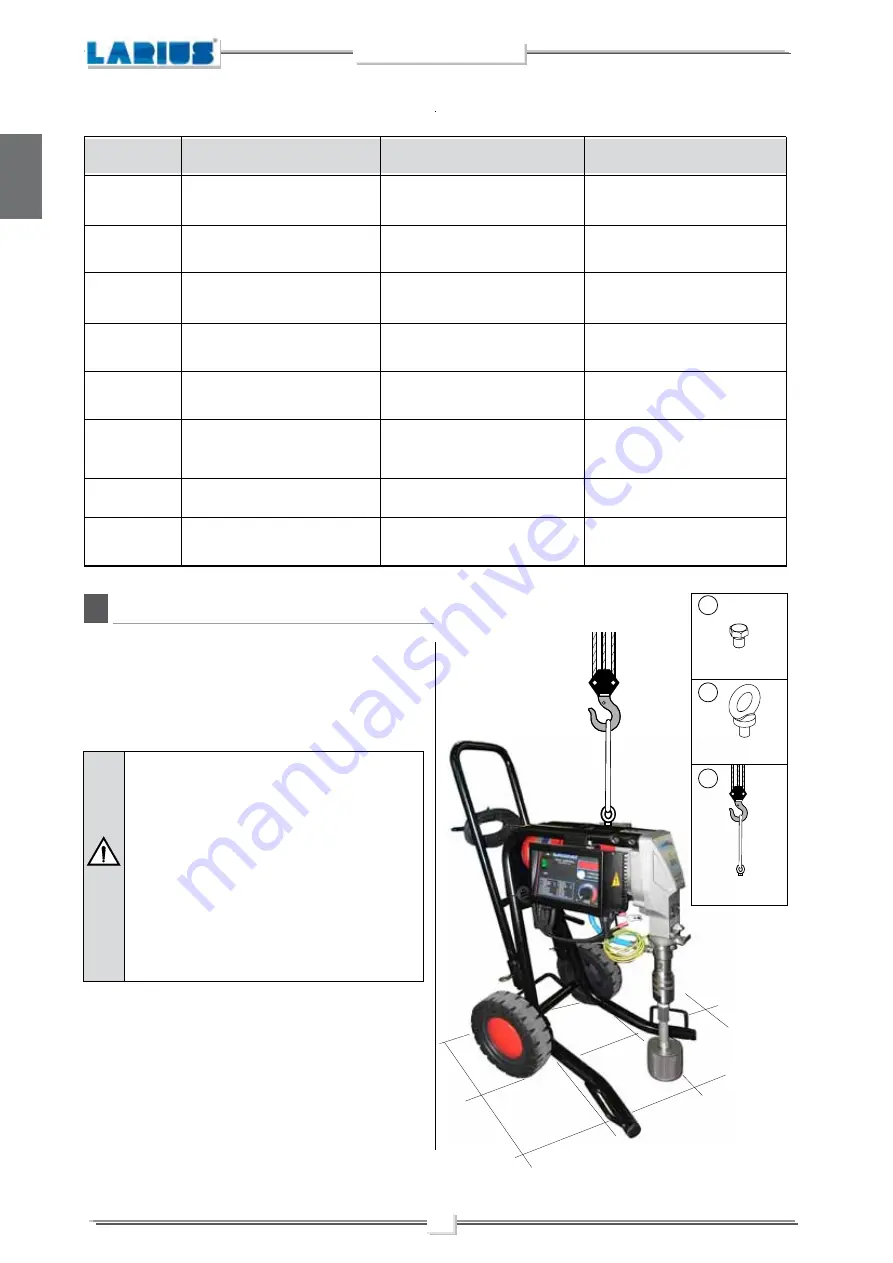

TRANSPORT AND UNPACKING

• The packed parts should be handled as indicated in the

symbols and markings on the outside of the packing.

•

Before installing the equipment, ensure that the area to

be used is large enough for such purposes, is properly lit

and has a clean, smooth floor surface.

• The manufacturer will not be responsible for the unloading

operations and transport to the workplace of the machine.

LIFTING POINTS

There are no precise lifting points for the machine in its entirety. In

order to determine the most appropriate lifting points, refer to the

geometric characteristics of the machine itself

(proceed as shown)

.

The user is responsible for the operations of

unloading and handling and should use the ma-

ximum care so as not to damage the individual

parts or injure anyone.

To perform the unloading operation, use only

qualified and trained personnel

(truck and cra-

ne operators, etc.)

and also suitable hoisting

equipment for the weight of the installation or

its parts. Follow carefully all the safety rules.

The personnel must be equipped with the ne-

cessary safety clothing.

REMOVE THE SCREW

SCREW IN THE

SUPPLIED EYEBOLT

LIFT THE MACHINE

1

2

3