ZEUS

22

English

I

H2

OFF

Rif. 16325

I1

I3

I2

I4

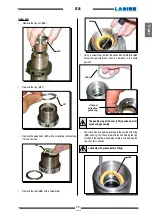

CHECK ON THE PACKING NUT

The gaskets do not need adjusting. The ring nut is only used to

fit and remove gaskets and for topping up the oil.

ROUTINE MAINTENANCE

Follow the washing procedure before using again

the equipment.

Always disconnect the electrical supply and

discharge the pressure in the pump unit

(open

the discharge valve)

before carrying out any

maintenance.

Wait 30 seconds before proceeding with mainte-

nance operations to allow any residual electricity

to be discharged.

•

In case of long storage, we recommend you to suck and to

leave light mineral oil inside the pumping group and the flexible

hose.

•

The ring nut (

I2

) must be tightened all the way.

Every 100 working hours, with the pressure at 0 bar, check

that it is tightened all the way.

•

The supplied pin (

I3

– ref. 20144) also serves the purpose of

closing and opening the pump unit’s locking ring-nut (

I4

). This

ring nut must always be closed in order to act as a locking

counter-nut.

•

Use the lubricant (

I1

) provided

(ref. 16325)

to make it easier

to slide the piston inside the seal pack and to substitute the

air with oil.

If the equipment is to be stopped for a lengthy period

of time, carry out the cleaning operations described

previously, according to the type of product used.

In case of short stoppages, suck in some water

and leave the pump unit in the bucket (H6) for a

few minutes.

At the start of each working day check that the

ring nut is full of hydraulic oil (Ref. 16325). This oil

makes it easier for the piston to slide and prevents

any material that escapes via the seal gasket drying

when the equipment is stopped.

Oil ring

Ref. 20144

Closing/opening

pin