Larson Electronics, LLC

Phone: (800) 369-6671

Fax: (903) 498-3364

www.larsonelectronics.com

2

of

4

IND-AHF-BX-UVC-R4-120V-15C

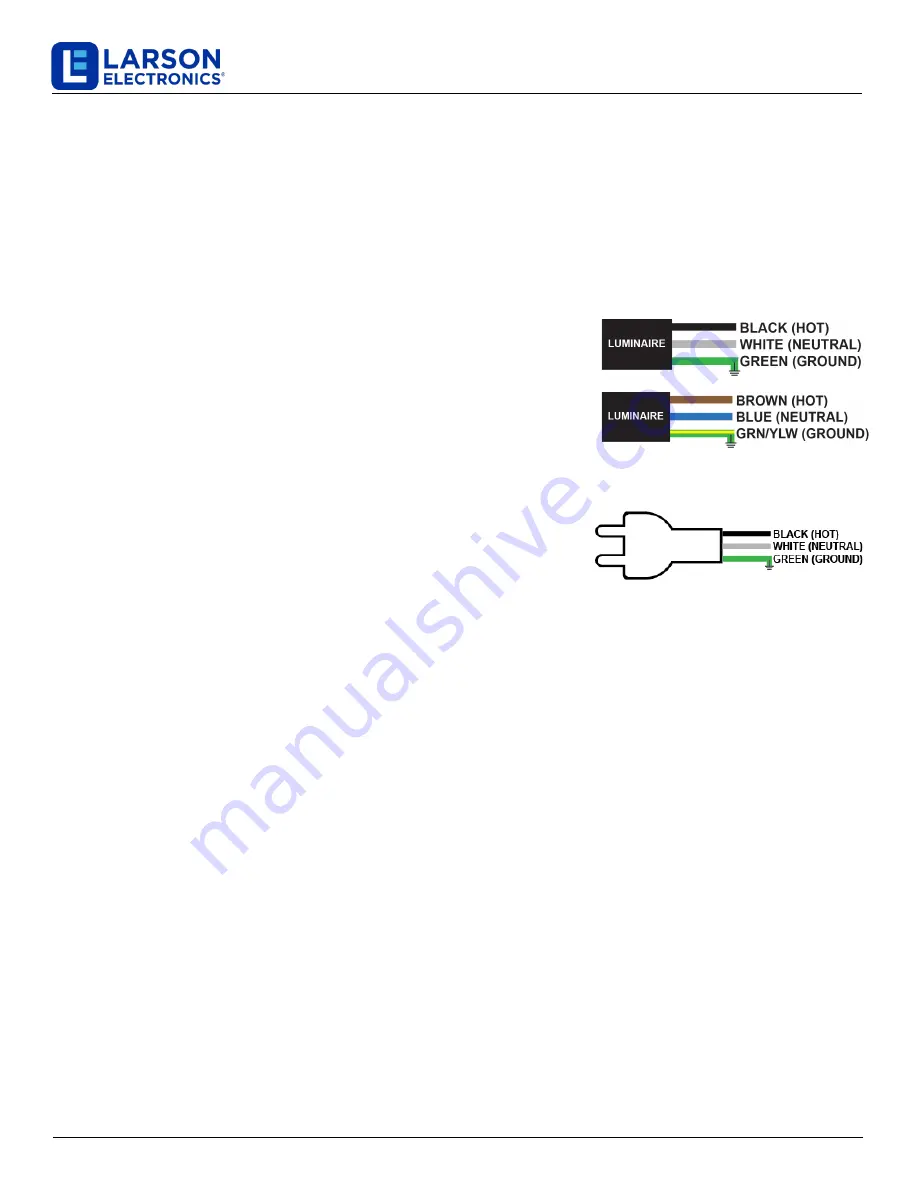

Attach supply line wires to the appropriate light fixture wires as shown

in the diagram

Secure each pair of wires according to the diagram. Utilize a junction box or

similar device and take precautionary steps for weatherproofing all

connections if installed in a location where water may come in contact with the

unit. Ensure the unit is properly grounded and that wiring is done according to

all local and national electrical/building codes.

Standard Cord Cap

This unit comes pre-wired from factory with the selected cord cap. Take

precautionary steps for weatherproofing all connections if installed in a

location where water may come in contact with the unit. All outdoor

installations and indoor installations near a wet location require the use of a

GFCI device for safety, according to the National Electrical Code® (NEC).

Ensure the unit is properly grounded.

WIRING

/PLUG

This unit is equipped with 15 feet of 16/3 chemical and abrasion resistant SOOW cord that is fitted with an industrial grade

cord cap for easy connection to common wall outlets. Plug options include standard 5-15 15 amp straight blade plug for

110V wall outlets with ground or NEMA L5-15 15 amp twist lock plug for 125V twist lock outlets. Alternatively, we can

provide flying leads with no plug for hard wire applications or for operators who prefer to wire in user provided cord caps.

Please choose pigtail option below for flying leads with no plug.

Standard pigtail(flying leads) wiring

We strongly encourage a licensed electrician install this product

, in all locations especially in outdoor areas

where weatherproofing may be required. Universal voltage driver permits operation at

120V AC.

Warning:

Check product label for correct input voltage!

MOUNTING

The

IND-AHF-BX-UVC-R4-120V-15C

is a ceiling mount unit that is equipped with a bracket making it compatible

with 2x4

troffer mount features for installations on ceilings with tiles or grids.

OPERATION

Surrounding "dirty" air is drawn into the UV purifier via washable electrostatic filters. The "dirty" air passes through the UV

sanitation chamber where it is treated with UVC light using the two T8 fluorescent lamps. The disinfection process kills up to

99.9% of viruses, bacteria, mold, spores and other harmful microbes. Clean sanitized air exits the chamber through a

louvered exhaust panel and is released back into the environment. This low-maintenance air disinfection process

is continuous and quiet.