3

INSTRUCTION MANUAL

Column Press with Electrical Pump "EE25030-CE"

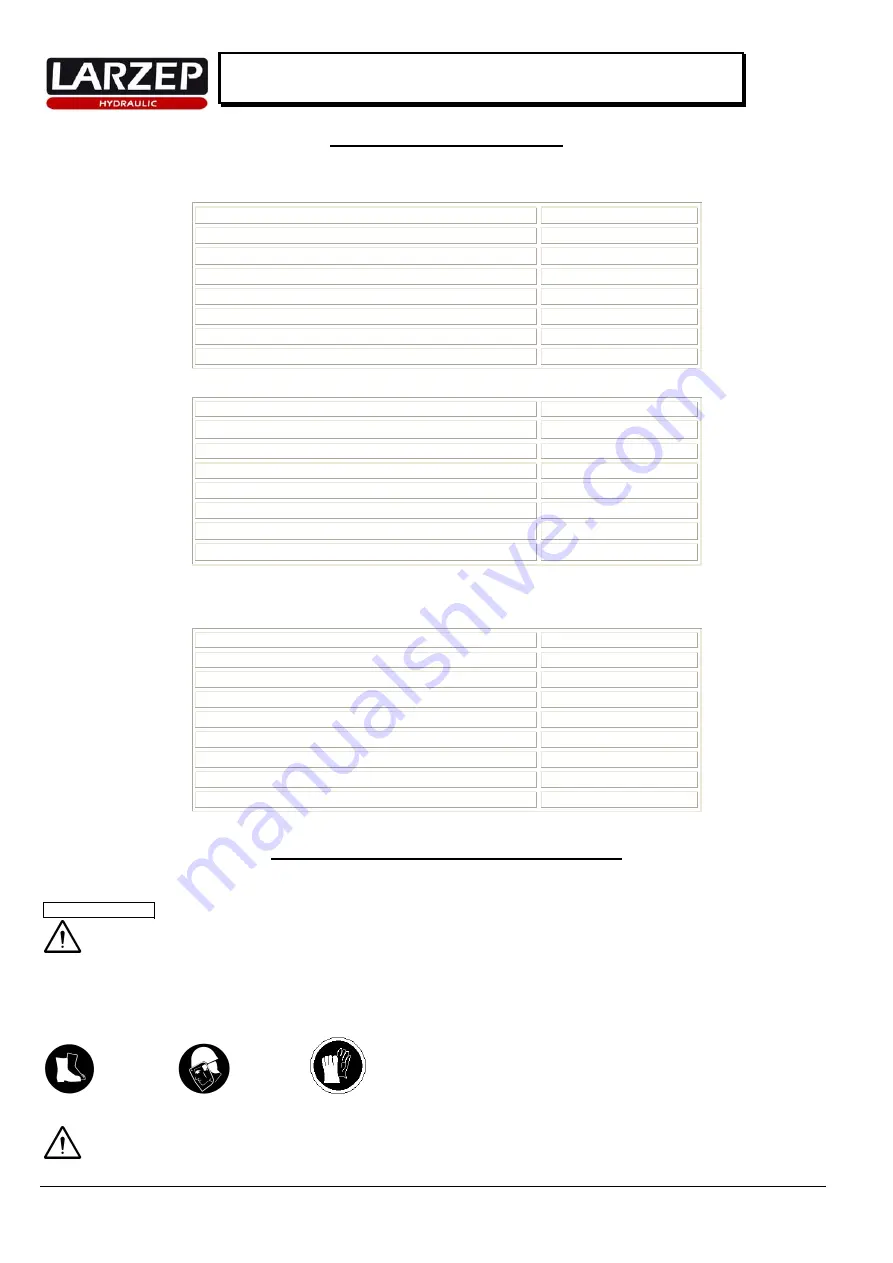

2. TECHNICAL FEATURES.

CYLINDER

MODEL D25030

•

Max. Pushing Capacity (Tn.)

242,3 Tn

•

Working max. pressure (Kg/cm

²

)

700 Kg/cm

²

•

Stroke (mm.)

300 mm.

•

Effective Area

346,3 cm

²

•

Oil capacity (cc)

10.390 cm³

•

Free advance speed (mm/sg)

4,5 mm/sg

•

Max. Pressure advance speed

0,6 mm/sg

POWER PACK

MODEL HAM8544B

•

Tank capacity (cc)

25 Litres

•

Volume in low pressure. Approaching

13 L/min.

•

Volume in high pressure. Working

2,2 L/min.

•

Maximum return pressure (Kg/cm

²

)

400 Kg/cm

²

•

Maximum working pressure (Kg/cm

²

)

700 Kg/cm

²

•

Distributor valve

Handle: 4ways, 3 positions

•

Motor

4 kW 400V 50Hz 3 ph

WELDED-MECHANIZED FRAME

MODEL

EE25030-CE

•

Working height maximum (mm.)

1022 mm

•

Working height minimum (mm.)

122 mm

•

Working Width (mm.)

1080 mm.

•

Total weight of the machine (Kg.)

2220 Kg.

•

Total height

2256 mm

•

Total width

1640 mm

•

Total depth

1000 mm

•

Displacement of the table

225 mm

3. ESSENTIAL SAFETY REQUIREMENTS.

3.1

GENERAL CONDITIONS.

DANGEROUS AREA

The speed of the hydraulic cylinder during its extension is less than 30 mm/second. Therefore then machine should be considered by the application of ANNEX V of

the Declaration of CE Conformity.

Operators standing in the dangerous area around the machine should protect their feet, faces and hands from metal pieces being ejected during pressing.

Feet protection

Face protection

Hands protection

Used materials and components are not for the health and safety of operators. The hand pump contains LARZEP hydraulic oil ISO: HV46.

Due to the

FUNCTIONAL REASONS

it is considered to be the space between the columns, the bed and the hydraulic cylinder piston.

Due to the

MATERIAL PRESSED

it is supposed to be surrounding area to the machine in case of metal parts being ejected during pressing.

HIDRAULIC OIL IS TOXIC IF IT ENTERS THE BLOODS STREAM. NEVER PLACE A FINGER OVER ANY ORIFICE OR LEAK, WHICH

COULD BE PRESSURIZED, SUCH AS THE HYDRAULIC LINE, AS THIS COULD CAUSE OIL TO BE INJECTED INTO BLOOD STREAM.

Summary of Contents for EE25030-CE

Page 7: ...7 INSTRUCTION MANUAL Column Press with Electrical Pump EE25030 CE 8 DECLARATION OF CONFORMITY ...

Page 8: ...8 INSTRUCTION MANUAL Column Press with Electrical Pump EE25030 CE ...

Page 9: ...9 INSTRUCTION MANUAL Column Press with Electrical Pump EE25030 CE ...

Page 10: ...10 INSTRUCTION MANUAL Column Press with Electrical Pump EE25030 CE ...

Page 11: ...11 INSTRUCTION MANUAL Column Press with Electrical Pump EE25030 CE ...

Page 12: ...12 INSTRUCTION MANUAL Column Press with Electrical Pump EE25030 CE ...

Page 13: ...13 INSTRUCTION MANUAL Column Press with Electrical Pump EE25030 CE ...