4

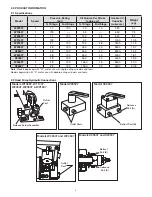

Pump Reservoir Type and Operating Position

Model

Reservoir Type:

Operating Position:

W20307

Non-Vented

Horizontal or Vertical

W10607

Non-Vented

Horizontal or Vertical

W20807

Non-Vented

Horizontal or Vertical

W11407

Non-Vented

Horizontal or Vertical

W21807

Non-Vented

Horizontal or Vertical

W22607

Non-Vented

Horizontal or Vertical

X22607

Non-Vented

Horizontal or Vertical

W24507

Vented (Type A)

Horizontal Only

X24507

Vented (Type A)

Horizontal Only

W26507

Vented (Type B)

Horizontal Only

X26507

Vented (Type B)

Horizontal Only

3.0 INSTALLATION

3.1 Hydraulic Connections

1. Remove shipping plug(s) from pump outlet port(s) and

discard.

2. All hand pumps have ⅜" NPTF threaded port(s). Use

1 1/2 wraps of Teflon tape (or suitable thread sealant)

on hose fitting, leaving the first complete thread free of

tape to ensure that tape does not enter into hydraulic

system, causing damage.

3. Install a pressure gauge in-line from the pump for

added safety and better control.

4. Connect the hydraulic hose(s) to your cylinder or tool.

After making connections, refer to Section 4.6 for

correct air removal procedure.

a. For single-acting cylinders, connect one hose from

the pump outlet port to the cylinder advance/retract

port.

b. For double-acting cylinders, use two hoses.

Connect the first hose from the pump advance

port (A) to the cylinder advance port. Connect the

second hose from the pump retract port (B) to the

cylinder retract port.

WARNING

One or more shipping plugs are used to

prevent residual oil from leaking out of port(s) during

shipment. Do not operate pump with the shipping plug(s)

installed. Oil may be expelled if pump is operated with

plug(s) installed.

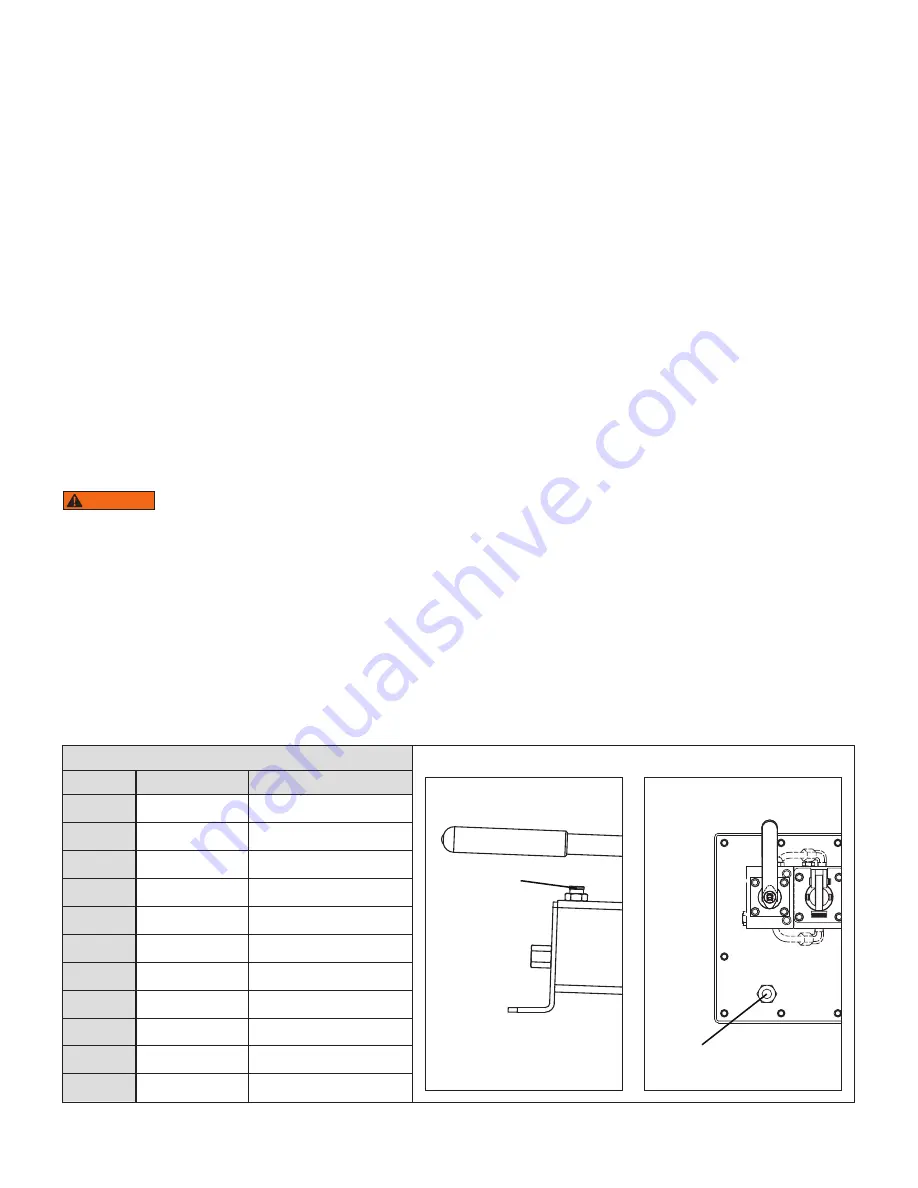

3.2 Pump Venting

The pump will have either a vented or non-vented style

reservoir. Refer to the table below to determine the type of

reservoir used on your pump.

3.3 Reservoir Vent

(models W24507, X24507, W26507 and X26507)

• The vent must be opened to allow pump operation.

If the vent is blocked or closed, the pump will not

function properly or will be inoperative.

• Turn the vent screw counterclockwise to open

the vent. To close the vent, turn the vent screw

clockwise.

3.4 Pump Positioning

Pumps with vented reservoirs must be operated in the

horizontal position only. Pumps with non-vented reservoirs

can be operated in either the horizontal or vertical position.

See the table below.

When using a non-vented pump in the vertical position it

is important to place the unit with the pump head facing

down towards the earth and the pump handle facing

upwards towards the sky.

Vent Locations (vented models only)

Type A

Vent

Screw

Vent

Screw

Type B