PLMNL0252 REV. B Effective Date: 10/16/17

39

FiberCUT

®

HR Operation Manual

6. Lay a piece of clean lens tissue on the

surface of the optic. With an

eyedropper squeeze a few drops of

reagent grade acetone on the lens

tissue wetting the complete area of

the optic.

7. Without lifting the dampened lens

tissue, drag the tissue across the optic

just fast enough so the acetone

evaporates behind the tissue.

If it is done correctly there will be

no streaks left on the optic.

It may be necessary to repeat

steps 6 and 7 multiple times.

If steps 5 to 7 do not remove all

contamination, proceed to

to replace the focusing mirror.

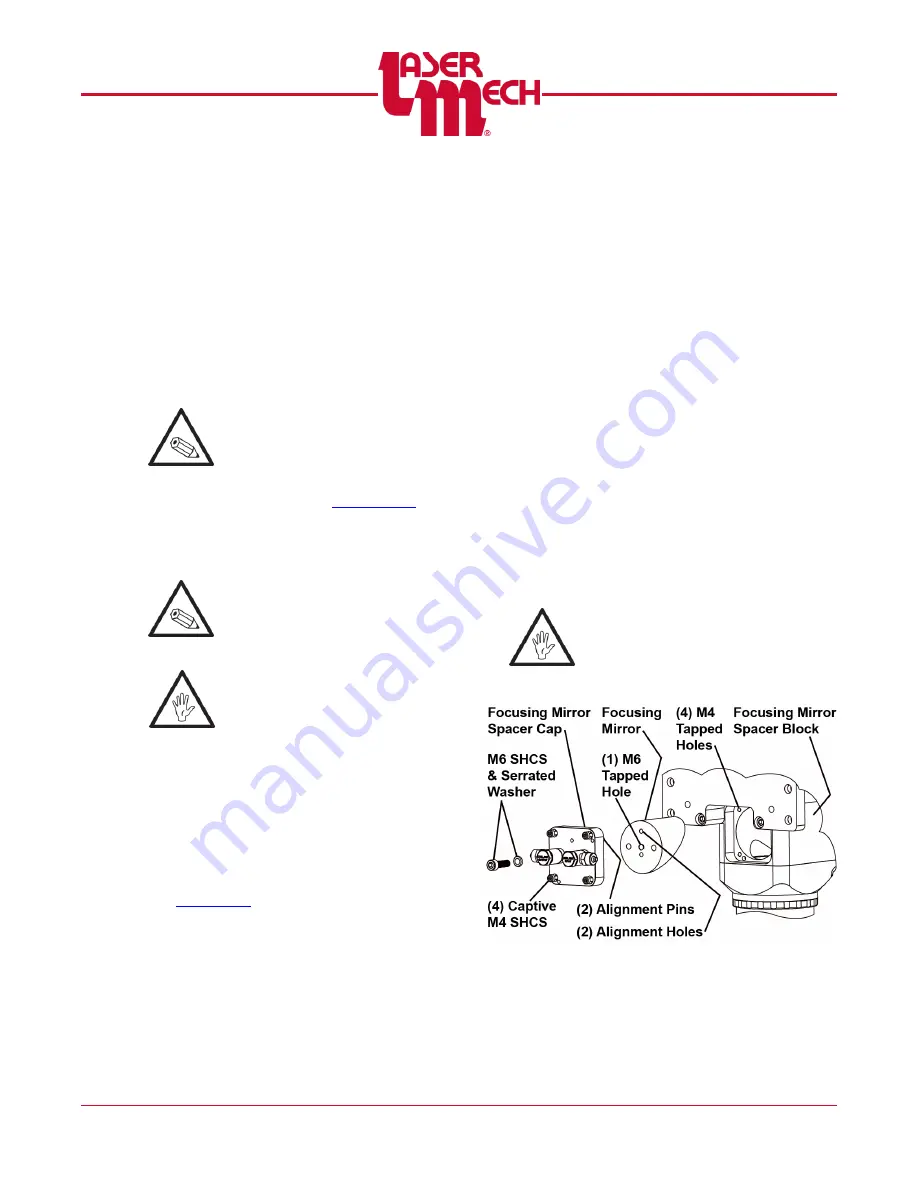

5.10 Replacing the Focusing Mirror

Perform the instructions in this

section ONLY if there is a

problem with the mirror.

Before opening any part of the

head, clean off the dust and/or

process debris using an

exterior cleaning towel

(PLTLS0023) or equivalent.

If the head is not removed and

relocated to a clean area already, see

step 1.

If the head is removed and relocated

to a clean area, proceed to step 2.

1. Remove the focusing mirror spacer

cap and focusing mirror according to

For steps 2 to 8, see

2. Remove the M6 SHCS and serrated

washer securing the focusing mirror

spacer cap to the focusing mirror.

3. Remove the focusing mirror, but keep

the M6 SHCS and serrated washer.

4. Align a new focusing mirror so:

The M6 threaded hole in the

center is in line with the M6 hole in

the focusing mirror spacer cap.

The (2) alignment holes are in line

properly with the (2) keyed

alignment pins in the focusing

mirror spacer cap.

5. Insert and tighten the M6 SHCS and

M6 serrated washer.

Hold the mirror against rotation

force applied by the M6 SHCS.

6. Align the focusing mirror spacer cap

and focusing mirror so the (4) captive

M4 SHCS are in line with the (4) M4

threaded holes in the focusing mirror

spacer block.

7.

CAREFULLY

insert the focusing

mirror spacer cap and focusing mirror

straight into the focusing mirror spacer

block.

Take care not to damage the sides of

the focusing mirror by contacting the

focusing mirror spacer block.

8. Tighten the (4) captive M4 SHCS.

Figure 60