PLMNL0252 REV. B Effective Date: 10/16/17

44

FiberCUT

®

HR Operation Manual

9 Appendix B

– Coolant Specifications

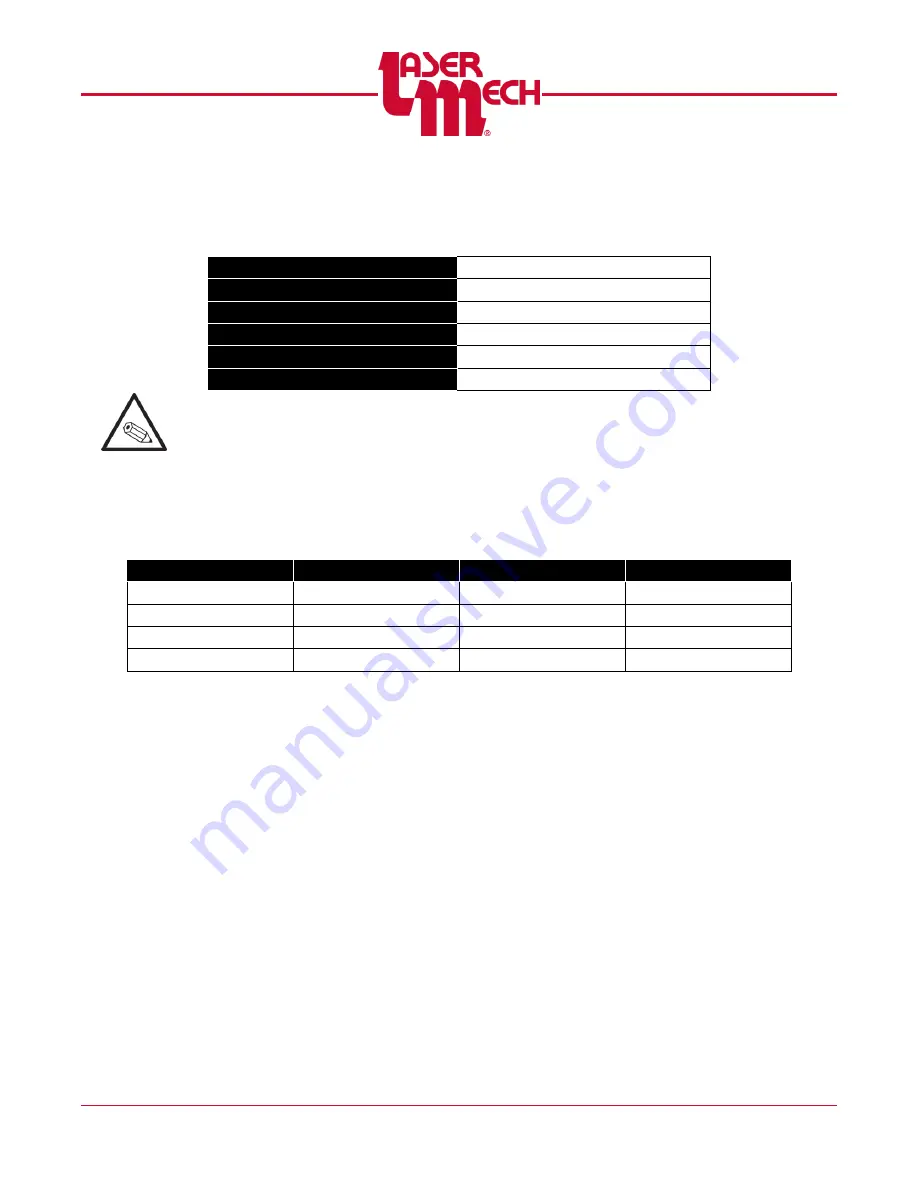

The cooling manifolds are designed to be operated on either a closed-loop cooling system or facility tap

water. The system must be a non-DI water circuit. For either type of system, the requirements in the table

below must be met.

Minimum Flow Rate

1.5 liter/minute @ 2 BAR minimum

Inlet Pressure

5.0 Bar (72.5 psi) Max

Inlet Temperature

≥room temperature / >dew point

Hardness (Equivalent to CaCO

3

)

<250mg/liter

pH

6 to 8

Particulate Size

<200 microns in diameter

See the manufacturer’s specifications for information on cooling the fiber

10 Appendix C

– Assist Gas Specifications

Impurities in the assist gas such as hydrocarbons (THC) and moisture (H

2

O) can damage optics, cause

power fluctuations and result in inconsistent cuts. See the table below for recommended assist gas

specifications.

Impurities can also be picked up in the supply lines. Non-metallic materials can allow oxygen and moisture to

permeate the system and can be a source of dust and hydrocarbons. Stainless steel lines and fittings are

recommended. Use filters that remove particles down to .01 microns and purifiers that guard against oil or

water from getting into the optical system.

Regulators with a stainless steel diaphragm are recommended. Industrial regulators can aspirate air and the

neoprene diaphragm can be a source of hydrocarbons.

Inlet pressure: 25.9 Bar (375 psi)

11 Appendix D

– Beam Delivery Purge Specifications

The beam delivery system must be purged with clean, dry air {specification to meet or exceed ISO

8573.1:2001 Class 2.2.1};

Solids

<100 particles per cubic meter of 0.1-0.5 µm size, and <1 particle per cubic

meter of 0.5-0.1 µm;

Water

dew point <-40º C;

Oil

<0.1 mg per cubic meter. A self-regenerating desiccant air

dryer filter unit (PLKIT0188) is available as an option from Laser Mechanisms.

An inlet pressure of 0.5

– 0.7 Bar (7-10 psi) produces 15 – 20 mBar at the internal purge pressure sensor.

12 Appendix E

– Nozzle Cooling and Air Blast Specifications

The nozzle cooling and air blast systems must be supplied with clean, dry air {specification to meet or exceed

ISO 8573.1:2001 Class 2.4.2};

Solids

<100,000 particles per cubic meter of 0.1-0.5 µm size, and <1 particle

per cubic meter of 0.5-0.1 µm;

Water

dew point <+3º C;

Oil

<0.1 mg per cubic meter.

Inlet Pressure: 2.0

– 3.5 Bar (30.0 – 50.0 psi)

GAS

PURITY

MAX H

2

O ppm

MAX THC ppm

Oxygen

99.8%

<5 ppm

<1 ppm

Nitrogen

99.998%

<5 ppm

<1 ppm

Argon

99.998%

<5 ppm

<1 ppm

Helium

99.998%

<5 ppm

<1 ppm