Contents

Page No.

2

7

Introduction

The Digital Belt Tension Gauge is a professional instrument that offers a highly accurate

method of measuring and adjusting the tension of all types of rubber timing and auxiliary

drive belts fitted to motor vehicles and machinery (maximum belt width 36mm). Tension can

be displayed in a variety of standard and manufacturers’ units. Tension limits can be set into

the instrument by the user.

During belt tension measurement and adjustment, the belt tension can be displayed on

the

visual display

and also via an

audible beep

. The audible beep changes depending on

whether the tension is within or outside the user’s set limits.

This avoids the user having

to read the display while adjusting the belt

. The selected tension limits, measurement

units and calibration parameters are stored in the memory of the tester, and remain in the

memory even when the instrument is switched off and the batteries removed.

The gauge can communicate with a PC computer for statistics recording and printing by

connecting the optional cable and software for USB interface.

Principle of Operation

The measuring head is placed on the belt and the clamp is tightened using the clamping

knob (finger tight only). This deflects the belt through a known angle defined by the anvil

and the fixed pillars.

A load cell attached to the clamp measures the force required to deflect the belt, which is

proportional to the tension in the belt. The output signal from the load cell is fed into the

handset to be digitized and scaled to give the correct tension reading on the instrument

display.

Please read the following instructions carefully and always keep this manual with the

machine for reference.

For specific belt tension settings always refer to the vehicle/

machinery manufacturers data

.

Calibration Procedure

A feature of the Laser 5846 is its ability to be

easily recalibrated by the user.

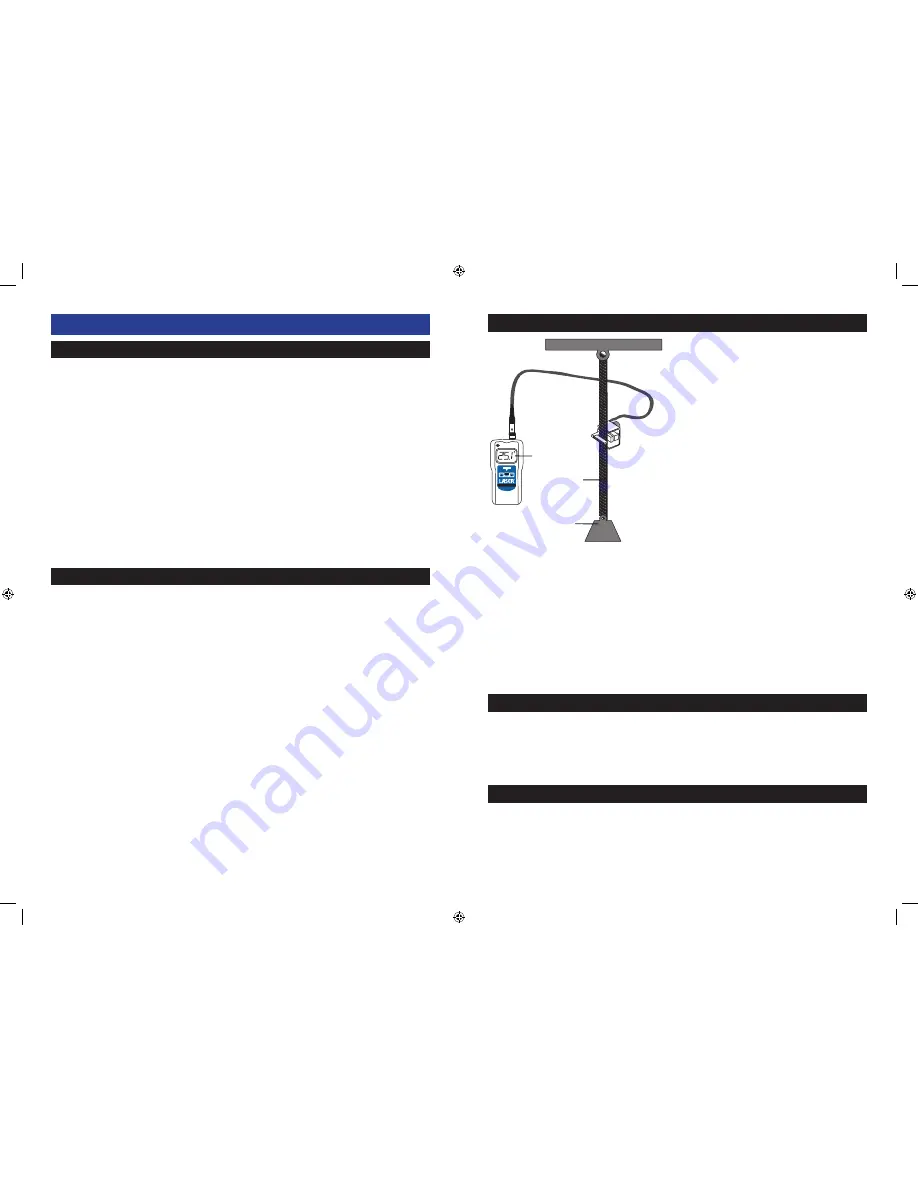

A calibration test-belt rig is set up using a

fixed and known weight (2)

. An

old cam

belt (1)

is first weighed then set up as per

the diagram. Make sure the cam belt is

connected securely to the suspension beam

and the weight.

The weight must be 25

kilograms minimum but can be higher

.

Switch on the 5846 handset. Clamp the

Measuring Head into position about half

way along the length of the belt. Turn the

clamping knob clockwise until the flat side of

the belt contacts the anvil, and a resistance

is felt. This should only be finger-tight.

Do not over tighten

.

A reading will show on the display. Wait until the reading has stabilized, then press and

hold the POWER key until

CAL

appears on the display. This is calibration mode. Change

the displayed value to the calibration weight. The calibration weight (

W

) is the sum of the

cam belt weight (

W1

) and the fixed known weight (

W2

). Thus in our example,

W = 25.1

(100g + 25kg). Use the UP and/or DOWN keys to enter the calibration weight into the

handset.

To save and quit, press the POWER key again for a few seconds.

Note

: If calibration mode (

CAL

) is entered and there is no weight connected or the weight

is less that 25kg, then

Err1

will show on the display.

LO OK HI

ZERO

UNIT

Belt Tension Gauge

5846

2 (W2)

25kg

1 (W1)

W = W1 = W2

W

Auto Power Off

If no key is pressed for approximately 10 minutes, the instrument will switch itself off to

save the battery. The unit can also be switched off at any time by holding down the power

on button until ‘OFF’ is shown on the screen.

Low Battery Indication

1. When the battery voltage is less than approximately 5v, the battery symbol will appear

on the display.

2. Slide the battery cover away from the instrument and remove batteries.

3. Install 4 x 1.5v AAA batteries correctly into the case.

4. If the instrument is not to be used for any extended period remove batteries.