6

3

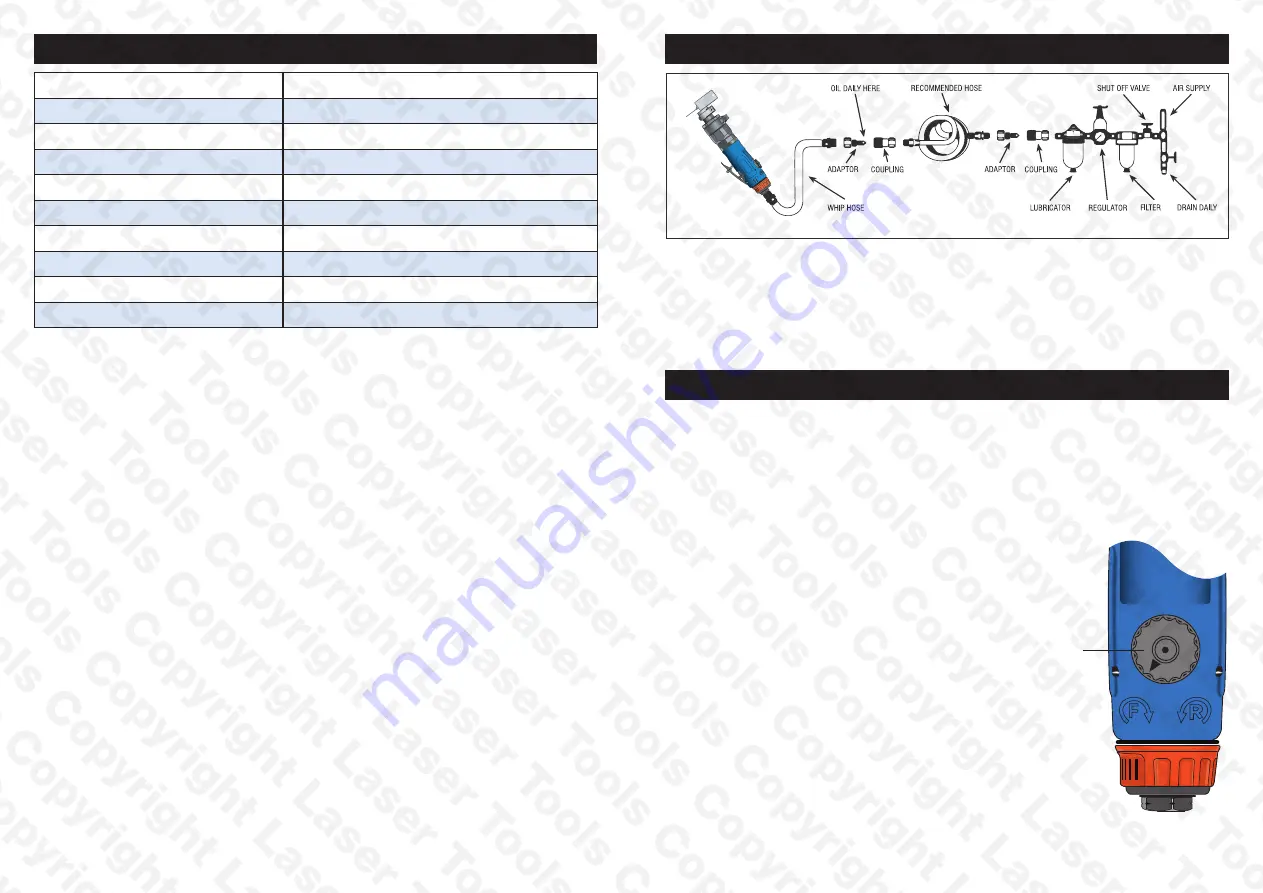

Compressed Air Supply

Operation

The tool must be connected to a suitable, clean, dry and lubricated workshop air supply (refer

to Figure 2, this is the recommended workshop air supply procedure). It is recommended

that the air pressure measures 90psi at the tool while running free. Water in the air line will

damage the tool. Drain the air tank daily and drain any dryer/filter unit when necessary.

Lubrication:

For first use of the tool, add a few drops of high quality air tool oil to the tool air inlet (

F

). In

use, if an in-line oiler is not installed, add a few drops of high quality air tool oil daily, squirted

into the tool air inlet. Adequate lubrication will help to ensure long tool service life.

Note

: after an air tool has been directly lubricated, oil will discharge through the exhaust port

during the first few seconds of operation. Cover the exhaust port (

E

) with a cloth to collect

this discharged oil.

When tool is not in use, disconnect from compressed air supply.

Regulating the speed:

Refer to

Figure 1

: the speed of the instrument is adjusted

by turning the speed control (

C

) towards LO or HI.

Cutting Wheel Direction: Forward or Reverse:

Refer to

Figure 3

: the cutting wheel direction (forward or

reverse) is set by turning the Forward/Reverse control (

D

)

to the left for forward, or to the right for reverse.

Fig 2

Fig 3

D

Disc / cutting wheel size

3" (75mm)

Horsepower

0.7

Weight

1.1kg (2.4 lbs)

Length

250mm

Guard rotation

360°

Free-speed RPM

16,000

Air inlet

1/4"

Recommended air hose size

3/8" internal diameter

Maximum air pressure

90psi (6.2 bar)

Average air consumption

3.6 CFM

Specifications

75mm cutting wheels are available from Connect Workshop Consumables: (Part No. 30460 -

pack of 5).