12

B

C

2,5 m

<

2 mm = OK

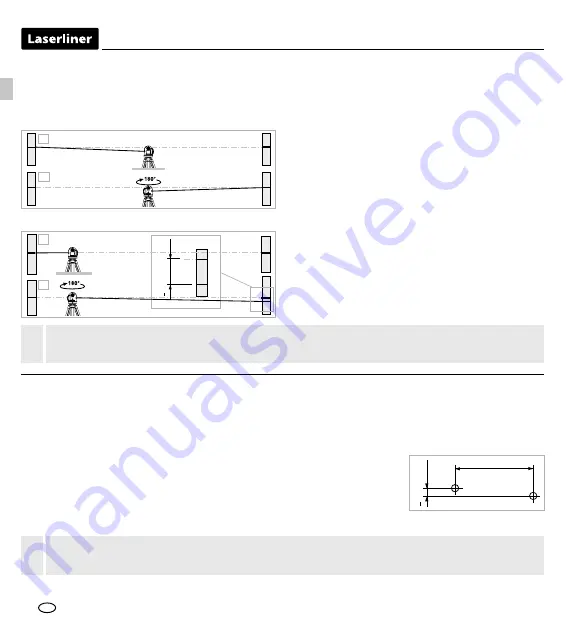

Checking the horizontal line

Position the device about 5 m from a wall and switch on the cross laser.

Mark point B on the wall. Turn the laser cross approx. 2.5 m to the

right and mark point C. Check whether the horizontal line from point C is

level with point B to within ± 2 mm. Repeat the process by turning the laser to the left.

Checking the vertical line

Position the device about 5 m from a wall. Fix a plumb bob with a line of 2.5 m length on the wall,

making sure that the bob can swing freely. Switch on the device and align the vertical laser to the

plumb line. The precision is within the specified tolerance if the deviation between the laser line and

the plumb line is not greater than ± 2 mm.

Regularly check the calibration before use, after transport and after extended periods of storage.

!

A1

A2

2.

1.

A3

A2

A2

A1

4.

3.

A3

A2

<

0,4

mm / m = OK

Preparing the calibration check

It is possible for you to check the calibration of the laser. To do this, position the device

midway

between 2 walls, which must be at least 5 m apart. Switch the device on

(Laser cross ON)

.

The best calibration results are achieved if the device is mounted on a tripod.

1.

Mark point A1 on the wall.

2.

Turn the device through 180° and mark point

A2. You now have a horizontal reference

between points A1 and A2.

Performing the calibration check

When A2 and A3 are more than 0.4 mm / m apart, an adjustment is necessary.

Contact your authorised dealer or else the UMAREX-LASERLINER Service Department.

!

3.

Position the device as near as possible to the

wall at the height of point A1.

4.

Turn the device through 180° and mark point

A3. The difference between points A2 and A3

is the tolerance.

EN

Summary of Contents for SmartLine-Laser G360

Page 74: ...74...

Page 75: ...SmartLine Laser G360 75...