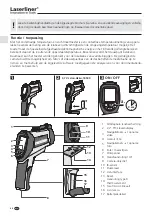

ThermoSpot-Vision

19

GB

17

Emissivity coef

Ƃ

cient / infrared measurement

A built-in sensor head detects the material/surface-speci

Ö

c infrared radiation emitted by all objects. The level

of these emissions is determined by the material's emissivity coef

Ö

cient (0.10 to 1.0). The emissivity coef

Ö

cient

must

Ö

rst be set in order to correctly measure the surface temperature. In addition to the de

Ö

ned emissivity

coef

Ö

cient, it is also possible to set an individual emissivity coef

Ö

cient (see Point 8).

Asbestos

Asphalt

Basalt

Coal

Non-oxidised

Graphite

Carborundum

Ceramics

Earthenware, matt

Clay

Concrete, plaster, mortar

Masonry

Brick, red

Lime malm brick

Fabric

Glass

Gravel

Gypsum

0,93

0,95

0,70

0,8 - 0,9

0,7 - 0,8

0,90

0,95

0,93

0,95

0,93 - 0,94

0,93

0,93

0,95

0,95

0,85 - 0,94

0,95

0,8 - 0,95

Ice

Clear

With heavy frost

Limestone

Paper

All colours

Wallpaper, light-coloured

Plastic

Translucent

PE, P, PVC

Soil

Water

Wood

Untreated

Beech, planed

China

Brilliant white

With glaze

Paint

Black, matt

Heat-resistant

White

0,93 - 0,98

0,97

0,98

0,98

0,95 - 0,97

0,88 - 0,90

0,80 - 0,95

0,95

0,94

0,9 - 0,98

0,93

0,8 - 0,95

0,94

0,7 - 0,75

0,92

0,96 - 0,98

0,92

0,85 - 0,95

Transformer paint

Rubber

Hard

Soft, grey

Cotton

Lime

Tar

Tar paper

Snow

Human skin

Quartz glass

Heat sink

Black, anodized

Marble

Black, dull finish

Greyish, polished

0,94

0,94 - 0,95

0,89

0,77

0,3 - 0,4

0,79 - 0,84

0,91 - 0,93

0,80

0,98

0,93

0,98

0,94

0,93

Nonmetals

Aluminium

Oxidised

Polished

Alloy A3003

Oxidised

Roughened

Brass

Polished

Oxidised

Copper

Oxidised

Elect. terminal strips

Haynes

Metal alloy

Inconel

Oxidised

Sandblasted

Electropolished

0,2 - 0,4

0,04 - 0,06

0,3

0,1 - 0,3

0,3

0,5

0,4 - 0,8

0,6

0,3 - 0,8

0,7 - 0,95

0,3 - 0,6

0,15

Iron

Oxidised

With rust

With red rust

Iron, cast

Oxidised

Non-oxidised

Molten mass

Iron, forged

Matt

Lead

Rough

Oxidised

Molybdenum

Oxidised

Nickel

Oxidised

Platinum

Black

0,5 - 0,9

0,5 - 0,7

0,61 - 0,85

0,6 - 0,95

0,2

0,2 - 0,3

0,9

0,4

0,2 - 0,6

0,2 - 0,6

0,2 - 0,6

0,9

Steel

Cold rolled

Ground plate

Polished plate

Alloy (8% nickel,

18% chromium)

Galvanised

Oxidised

Heavily oxidised

Freshly rolled

Rough, flat surface

Rusty, red

Sheet, nickel plated

Sheet, rolled

Zinc

Oxidised

0,7 - 0,9

0,4 - 0,6

0,1

0.35

0.28

0.80

0.88

0.24

0.95 - 0.98

0.69

0.11

0.56

0,1

Metals

The table lists several material-speci

Ö

c emissivity coef

Ö

cients that should be considered as reference

values. The shape and structure of the surface can in

×

uence the emissivity coef

Ö

cient.

!

Unknown emissivity coef

Ƃ

cient

Apply masking tape or matt black paint to the surface of the area to be measured. Wait until the

tape/paint has assumed the surface temperature. The temperature of the surface can then be measured

with an emissivity coef

Ö

cient of 0.95.

Summary of Contents for ThermoSpot-Vision

Page 222: ...222 ...

Page 223: ...ThermoSpot Vision 223 ...