PLMNL0199 REV. J Effective Date: 08/05/21

4

FiberCUT

®

ST Operation Manual

2.4 Fiber Input

The fiber input is where the fiber optic cable

plugs into the cutting head. See

There are several industrial standard styles

of fibers ends (QBH, QD/LLK-D, LCA,

Q5/LLK-B, HCL-8 & PIPA). See

for sample images of each. Each of

these fibers has a unique method of

securing it to the fiber input adapter. Refer

to the fiber

manufacturer’s information for

specific instructions.

2.5 Bundling

As in any robotic application, cables need

to be bundled in a manner allowing

complete tool movement without pinching

or pulling of the cables. The FiberCUT

®

head was designed so that all cables input

in the same location

– allowing a sleek,

easy-to-manage bundle.

Cabling should not be tethered to the fiber

input connector or the fiber optic cable.

The manner in which the cables are

bundled is one of the keys to having

a successful robotic cutting cell. The

end user is responsible for

documenting and training personnel

on the best bundling methods for

their application.

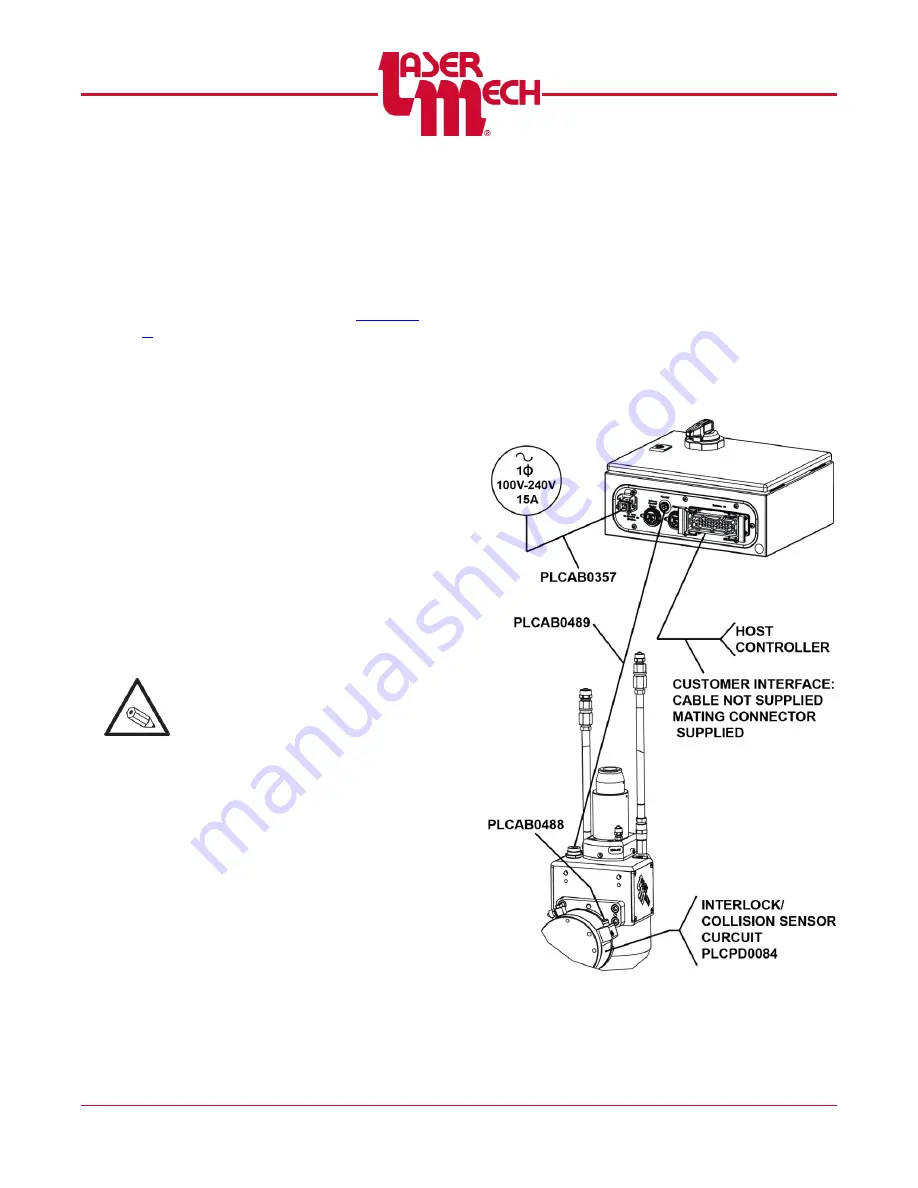

2.6 Electrical Wiring

There can be two electrical wires

connected to the cutting head. See

One is the communication cable

between the cutting head and the

control box (PLCAB0489).

The other is the optional collision

sensor cable that is plugged into the

robot system interlock (PLCAB0488).

Figure 7