PLMNL0199 REV. J Effective Date: 08/05/21

1

FiberCUT

®

ST Operation Manual

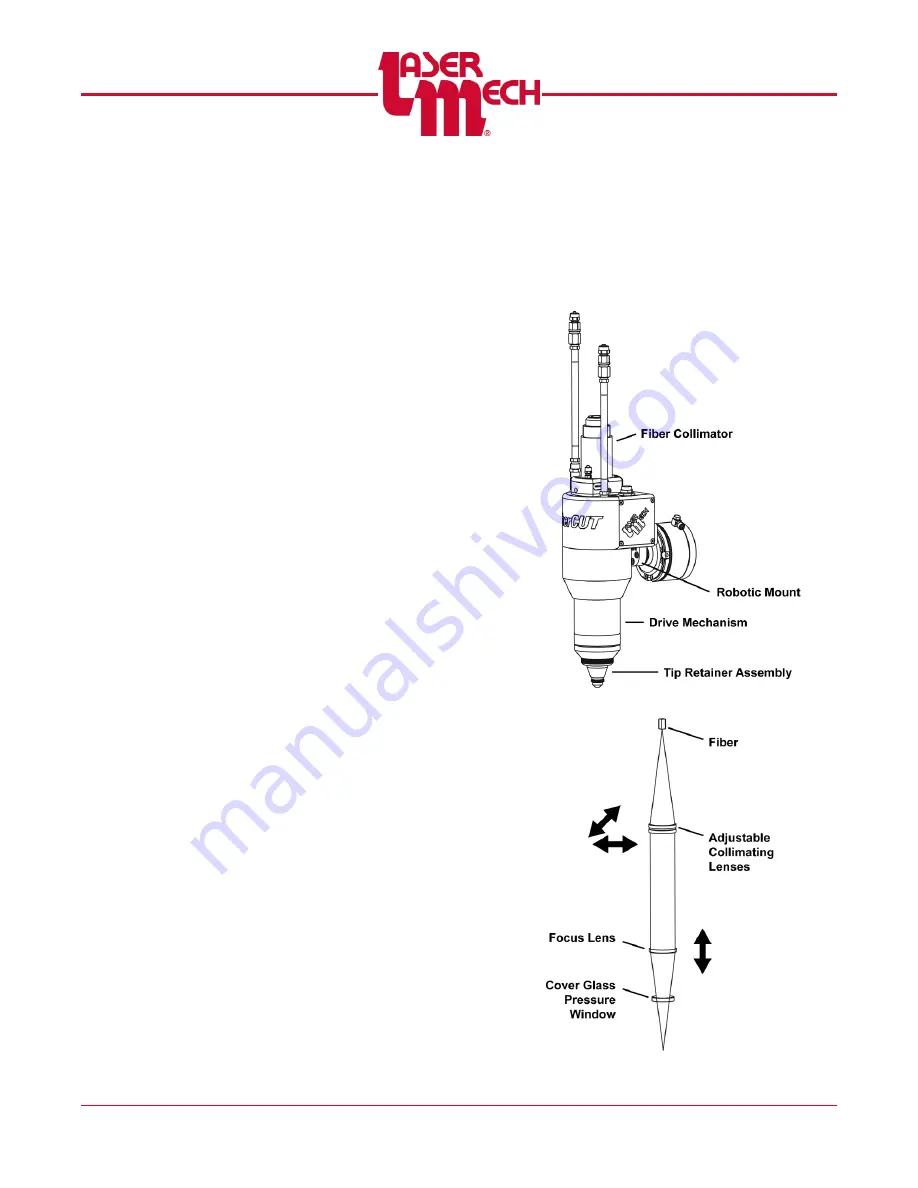

1 Introduction

The FiberCUT

®

robotic laser processing head

was developed to work in the most extreme

manufacturing environments. The straight input

of all connections, including the fiber, optimizes

the ability of the robot to utilize its complete

working envelope.

The FiberCUT

®

is made up of four main

subassemblies. See

The robotic mount

The fiber collimator assembly

The drive mechanism

The tip retainer assembly

for the path of the laser beam

through the FiberCUT

®

. The robotic mount

connects the cutting head to the robot, often

through an optional collision sensing device. The

fiber collimator unit uses a doublet collimating

lens to gather the laser light and collimate it after

it leaves the fiber optic cable.

A collimator focal length of 100mm is

standard (other focal lengths are available if

the application requires).

The laser beam then propagates through the

final focusing lens which focuses the laser

through the orifice of the gas jet tip. The drive

assembly provides the motion system that

allows the tip to track the surface of the part and

maintain laser focus.

The drive system has 25mm of travel and is

controlled by a patented drive system which

provides smooth, linear motion.

The tip retainer assembly contains the final

focusing lens and a cover glass that protects the

lens from dirt and debris. The lens housing is

threaded into the tip assembly.

The tip threads into the end of the tip

retainer and controls gas flow to the work

piece.

The tip retainer assembly also provides the

electrical feedback to maintain a constant

gap between the tip and part.

The tip retainer assembly comes in various

focal lengths and configurations, allowing

the end user to optimize the cutting head

configuration.

This manual explains the steps of installing,

setup, operation and service of a FiberCUT

®

robotic laser.

Figure 1

Figure 2