ICS-6 Instruction Manual

01000-53-000

Page 31 of 42

Issue 11 19 January 2021

6.2 Installing Expansion Boards

It is possible to install one expansion board into a standard ICS-6, however the space for wiring is

fairly restricted so a deep case option is available for ICS-6 which increases the depth of the unit

from 89mm to 145mm, which gives ample space for three or four expansion boards.

Note that the O-PCB override timer cannot be fitted at the same time as an expansion board.

To fit an expansion board, turn off and isolate the mains supply and open the ICS-6.

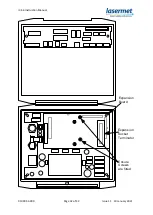

On the large circuit board on the inside of the ICS-6 cover, remove the ICS Expansion Control Socket

Terminator near the top right corner. Do not discard it as it will be needed shortly.

Locate the Expansion board onto the sockets on the large circuit board on the back of the door, such

that the holes in the expansion board align with the screw pillars in the circuit board behind. It is

most important that the holes are aligned with the pillars behind. Insert two M3 screws with shake

proof washers through the holes in the expansion board to secure it to the pillars. It is essential that

the expansion board is fitted the right way round and secured with the screws as it may otherwise

fall off, disabling the system. Refer to the diagram on the next page.

Make the necessary electrical connections to the expansion board according to its specific

instructions.

If further expansion boards are required, fit each one on top of the previous one using the same

method and ensuring that each is secured to the one below using the screws. It is usually easiest to

wire each one before fitting the next one on top.

Refit the ICS Expansion Control Socket Terminator to the socket in the top right corner on the

topmost expansion board as shown on the next page.