Laser Jailer Maintenance Manual

00892-53-000

Page 14 of 16

Issue 2 30 January 2020

Open Circuit

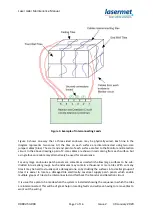

Lasermet supply a probe for locating open circuits. It comprises a signal source and a handheld

‘wand’. The signal source is connected to the cable. The wand is offered close to each tile in turn

following the order in which they are interconnected. A meter indicates whether or not the signal is

present and in this way the point of open circuit can be located.

The wand can also be useful for confirming that none of the tiles have been bypassed or missed out.

The unit is supplied with operating instructions.

If the probe is not available, the circuit can be checked with the multimeter. One way is to remove a

tile near the middle of the circuit and fit wires into the sockets of the remaining adjacent tiles such

that the two pins are connected together. The meter, on resistance range, is then put across A Start

and B Start. If the half circuit as far as the removed tile is OK a reading of less than 200kΩ should be

seen. This is repeated for the other half circuit by measuring the resistance between A End and B

End. Once the faulty half-circuit is found the tile is reconnected and replaced and a tile is removed

near the middle of that half-circuit and the test repeated. In this way it is possible to progressively

divide the circuit into smaller chunks until the fault is located.

Leakage

This technique can be used for faults between the two circuits, or between one circuit and earth.

If the failed resistance test indicates a low value (e.g. less than about 5kΩ) and the reading is steady

there could be an actual short circuit and its position can be predicted based on the theory that each

tile adds 66 ohms to the resistance. For example, if the reading was 594Ω from the start, one could

predict that the fault is around the ninth tile from the start (594/66=9). As a check, the resistance at

the end should be about 462Ω since the fault is 7 tiles from the end (462/66=7).

In other cases, it may be necessary to progressively remove tiles until the fault disappears. As in the

open circuit testing above the easiest way may be to remove the middle tile and test each half

circuit, then remove the middle tile of the affected half, and so on, repeatedly dividing the circuit in

half until the fault has been located.

6.5 Repair and Test

Once the failure has been found it can be repaired. If the fault concerns wiring or connectors it can

often be repaired in situ. If a tile has been damaged this may be visible in the form of burning. The

tile should be replaced, and spares are available from Lasermet. You will need to advise the size of

tile required when ordering.

Once the repair has been affected, the system should be restored to normal operation. With the

power turned on, reset the fault latch as described in Fault Latch Reset above and confirm that the

green Ready light is illuminated on the Monitor and Detection board or on the front panel of the

interlock controller. Ensure any other interlocks (e.g. doors, covers etc.) are closed. Press the Arm

Laser button and confirm that the interlock controller arms successfully.